Caroline Dallaire

Construction, Fabrication

Chaudière-Appalaches

Founded by the Dallaire brothers over 60 years ago, P.H. Tech has been creating doors and windows of the future right from the start. With its innovative products, high quality standards and a team of 325 passionate people, this Lévis-based flagship shines with excellence across Canada, the United States… and beyond!

Share on social medias

Share on social medias

The genesis...

Generations of products that revolutionized the industry

At the helm of P.H. Tech since 2015, Caroline Dallaire is proud to be taking over the family company founded by her father and uncle.

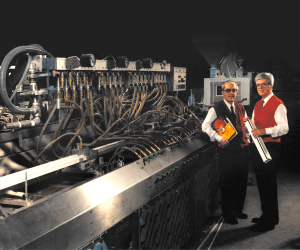

Raymond and Dominique are already in business when they found P.H. Tech in 1962. These general contractors in the Quebec City area build houses and are aware of how difficult it is to find quality doors and windows. Their clients often complain about that fact.

Ingenious and visionary, they then decide to take the initiative to create some themselves. By drawing up their plans for doors and windows, the two brothers pave the way for generations of products that have revolutionized the industry. Their passion and attention to quality open the doorsto success.

That’s often how companies get started. People see a need and decide to address it because there is nothing on the market that they like.

The production work begins!

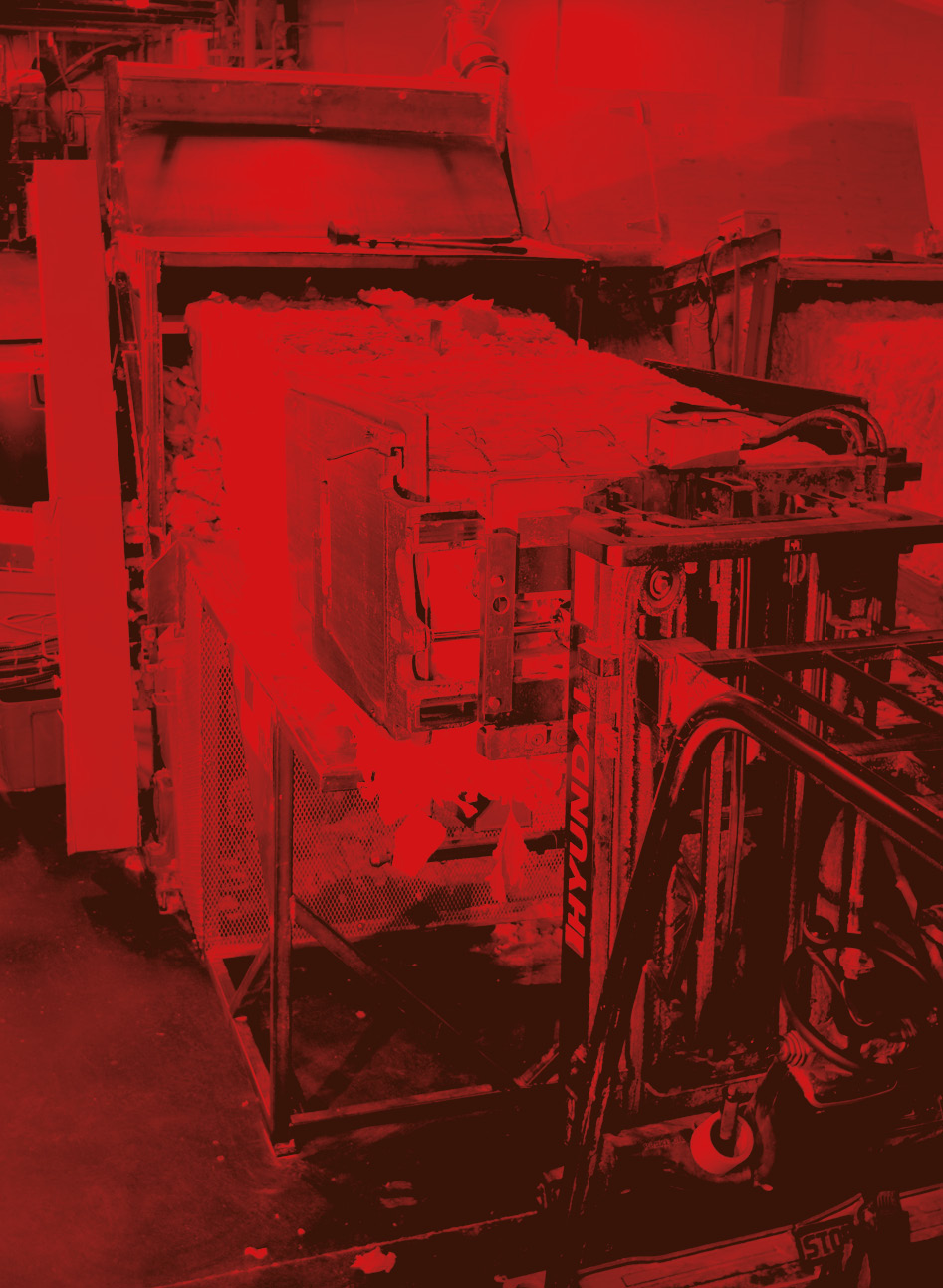

After a year or two, Raymond and Dominique take over the manufacturing themselves and start extrusion work in Lévis, renting spaces that they use as workshops. When P.H. Tech becomes financially self-sufficient, the Dallaire brothers close their construction business. “They devoted themselves solely to making doors and windows.”

From the 1970s onwards, they have a factory built in Lévis, which undergoes successive expansions, the latest of which is completed in 2018.

Because the founders aim for the right target with quality products in a market they are familiar with, P.H. Tech grows fast. “They knew construction. They knew what contractors needed.”

Recipients of international awards, their innovative products are also being exported to the United States and even Europe.

Construction

The material of the future!

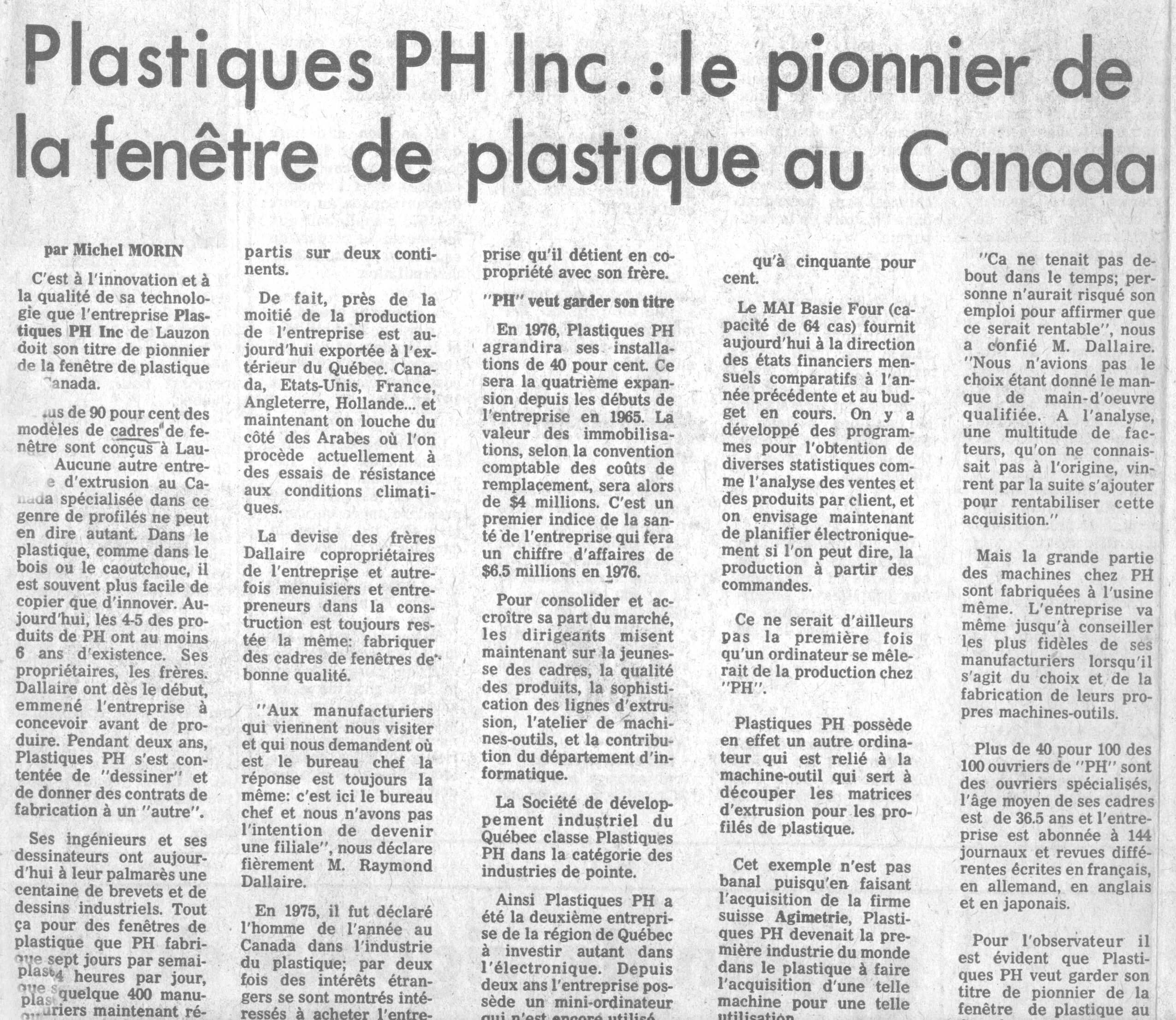

In the early 1960s, doors and windows in North America are essentially made of wood. Because they are regularly exposed to rain and water, they deteriorate rapidly and require a great deal of maintenance.

In their search for sustainable solutions, the Dallaire brothers begin to incorporate polyvinyl chloride (PVC), which is at the time hardly used, into their windows. They soon conclude that this is the material for the future.

In 1978, they become pioneers by designing wooden and PVC patio

doors to replace aluminum ones.

New generations of products, entirely made from PVC, are introduced at the end of the 1980s. “These were major steps in our development!”

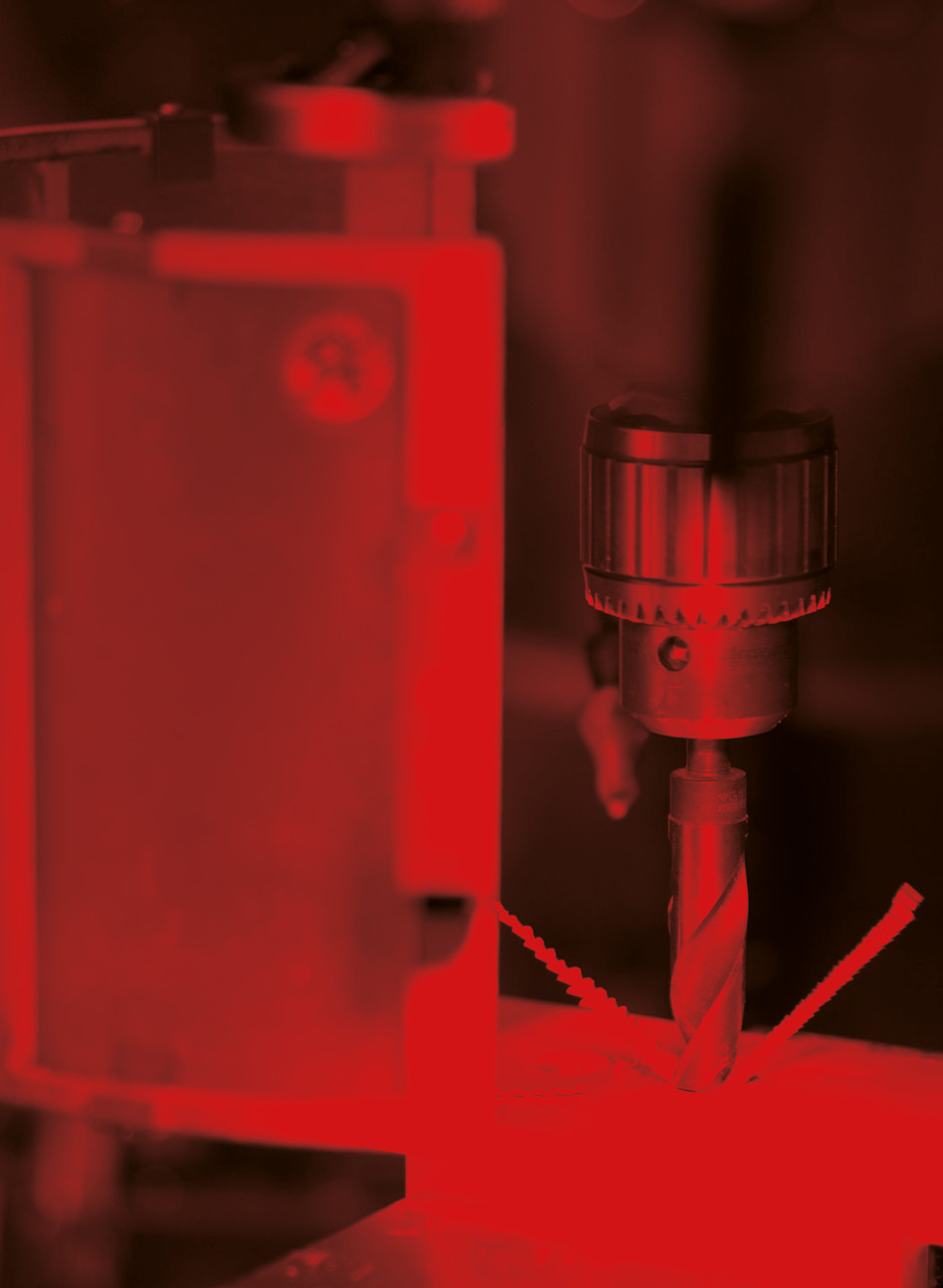

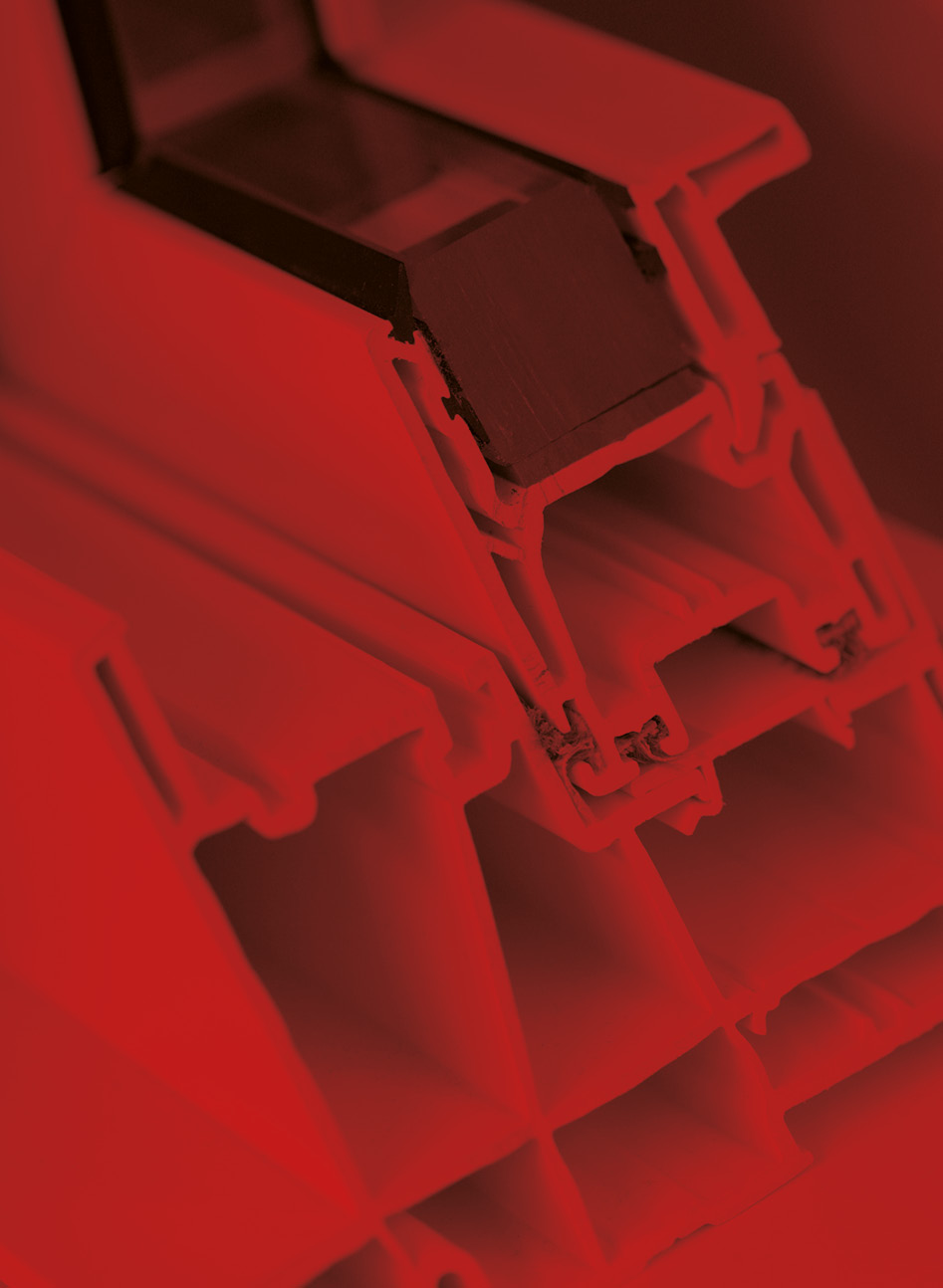

The team roll up their sleeves and change all their production equipment to adapt the new technology to the types of PVC used. By taking this bold step, P.H. Tech becomes a leader in the extrusion of patented PVC frames.

Le Soleil, 1976

Pioneers

Today, everything is PVC… we only have one wooden door left and there is no wood in our windows!

Closely knit with manufacturers

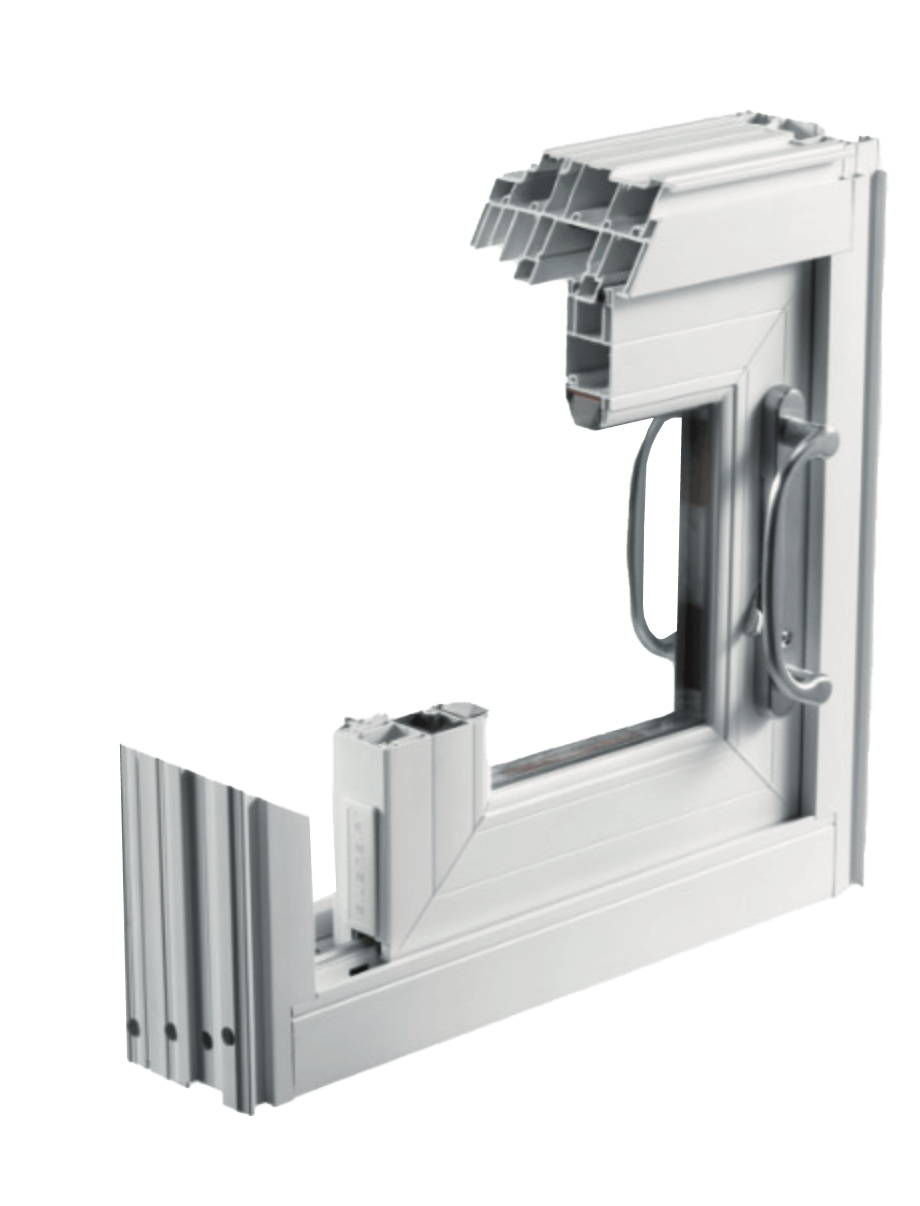

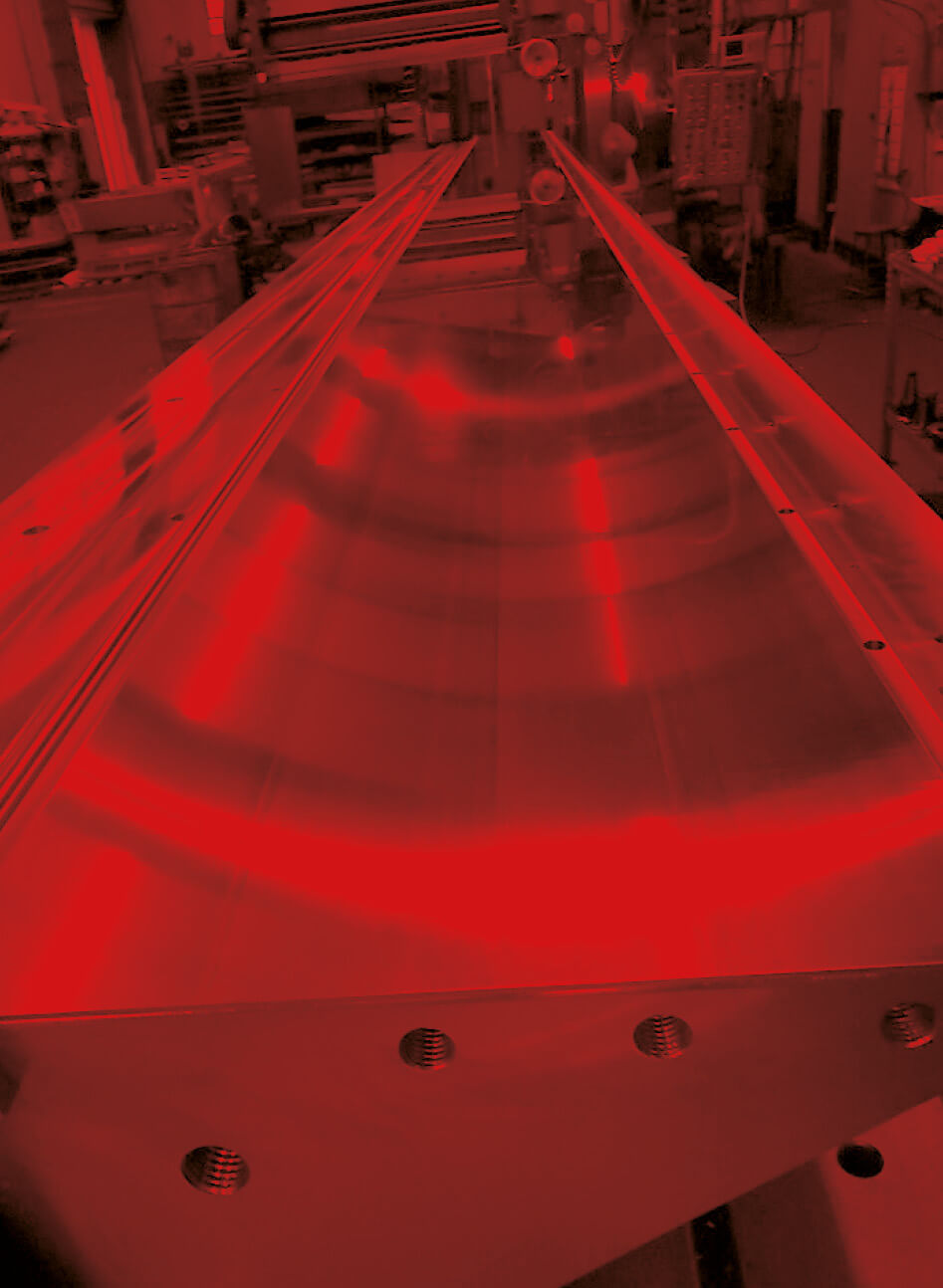

Each player in the door and window production chain has a clearly defined role. “We develop and test the products. We develop the moulds intended for the extrusions and we extrude.”

In other words, the team uses a PVC powder that passes through an extrusion line and takes on the desired shape according to the moulds selected. This continuous transformation process produces PVC profiles for doors and windows, which are then sent to manufacturers for assembly.

“We don’t sell to any consumer or distributor. Only to manufacturers!”

And the team develops a special relationship with them. With a turnkey service, it supports manufacturers so they can achieve the results they want. “This relationship is important to us!”

This link gives them the opportunity to be in touch with the manufacturer’s needs and enables the Research and Development (R&D) department to constantly come up with trendy products that deliver on their promises.

We’ve built our reputation on quality, durability and performance — that’s what sets us apart!

The only woman on the floor

Caroline first joins the company for a summer job in 1993, as she is studying industrial engineering at the École Polytechnique, in Montréal.

She is delighted to be working on so many engineering projects. Among other things, she has to identify new ways of supplying machinery with raw materials and implement a storage system to optimize space.

“I went back to school for my final year and a job as a plant engineer became available after my studies. I decided to come back because I thought it was fun!”

At the time, there are a few women working in the offices or in the ironmongery, but this young graduate is the only woman in production among the 70 or so men in the factory.

That didn’t stop me. I’ve had a lot of great guys who’ve helped me and pushed me forward. They took the time. I’ve had some good mentors!

Energy & passion

She dives!

Plunged into the thick of things, Caroline is given more and more responsibilities.

It wasn’t long before I was meeting clients and sitting on the management committee. One thing led to another, and I took on a bit more.

During this period, the two founders gradually withdraw from day-to-day operations, although they remain active on the board of directors. Raymond remains on the board until his passing in 2015. That same year, Caroline becomes president.

As for Dominique, he sells his shares and bows out three years later.

Caroline and a Canadian private equity fund then acquire the company and its subsidiaries in 2018. Unbridled growth awaits them…

Vision and values...

An accelerated takeoff

From the moment she takes over as president, Caroline, surrounded and supported by an extraordinary team, learns to move at great speed. P.H. Tech is off to a flying start.

From 2015 to today, sales have more than doubled. “There were rumbles… It was demanding, but we really took off. The sales, the company… everything has really exploded. It’s fun! It’s good for the future!”

Creation

The housing crisis in recent years and the shortage of labour contribute to stimulate the construction market, here as well as South of the border.

There is a shortage of labour everywhere. We want more immigrants, but we have to house them!

And with the pandemic, the renovation sector is also doing very well. “Confinement has increased the demand for renovation. Everyone used their money to invest in

their home.”

“These are really good years!”

Performance

Golden business with the neighbours

P.H. Tech makes major gains in the American market, which lost ground during the recession of 2006 to 2008, when a number of American doors and windows companies went out of business. The Lévis-based company seizes this golden opportunity.

“Over the last few years, we have made inroads in the United States. We have really seen great growth over there.”

This vast market on the other side of the border is the reason for the opening of a second assembly plant in Swainsboro, Georgia, in 2021. The first plant had opened in Leetsdale, Pennsylvania, in 1982.

The goal is to have a presence there so that American customers can buy from an American entity and feel at home with their suppliers.

P.H. Tech also serves all the Canadian provinces. From coast to coast, the demand is there.

We have loyal and successful business partners across Quebec and Canada.

Growth & loyalty

Eureka !

P.H. Tech continues to live up to its raison d’être,

driven by innovation in order to find solutions tailored to the needs and trends in different parts of the world.

What sells in Quebec is not necessarily what sells in British Columbia or the United States. Windows are a cultural thing! People don’t buy the same kinds of windows everywhere.

This is why P.H. Tech develops a wide range of models based on the needs of the respective markets. For example, Quebecers prefer casement windows that open with a crank, while Americans are more inclined toward sash or sliding windows.

The doors and windows are designed and tested to resist water and air infiltration as well as wind pressure, and they keep their promises.

If you install a P.H. window in your home, in 20 years, it’s still going to be there and it’s going to work just fine!

Weather has the last word

Adaptation

In fact, weather conditions have a major influence on the R&D team’s product design.

“The way we build wall thickness is not the same from one place to another. Our windows in Quebec are thicker because it’s cold. We build thicker, more insulated walls. It’s very specific to each region.”

And what can we say about the numerous tropical storms that prompt the R&D department to create hurricane-resistant windows to protect the inhabitants of Florida, for example!

Insurance companies have very high standards. Building codes have become very demanding, so we have adapted several products to meet the standards. It’s a great challenge!

Experienced challenge enthusiasts

Caroline studied industrial engineering and is particularly driven by special projects. If she is asked to produce a PVC window that looks like wood, her team will oblige.

We developed a technology where we were able to modify the finish and dye the PVC. We worked a long time in order to do that!

These passionate people also love to rack their brains to create eco-responsible products that integrate recycled materials.

P.H. Tech is proud of its latest patio door creation, which features three panels instead of two. “We developed sliding doors that provide

more open space.”

Projects

Reaching out to industry players

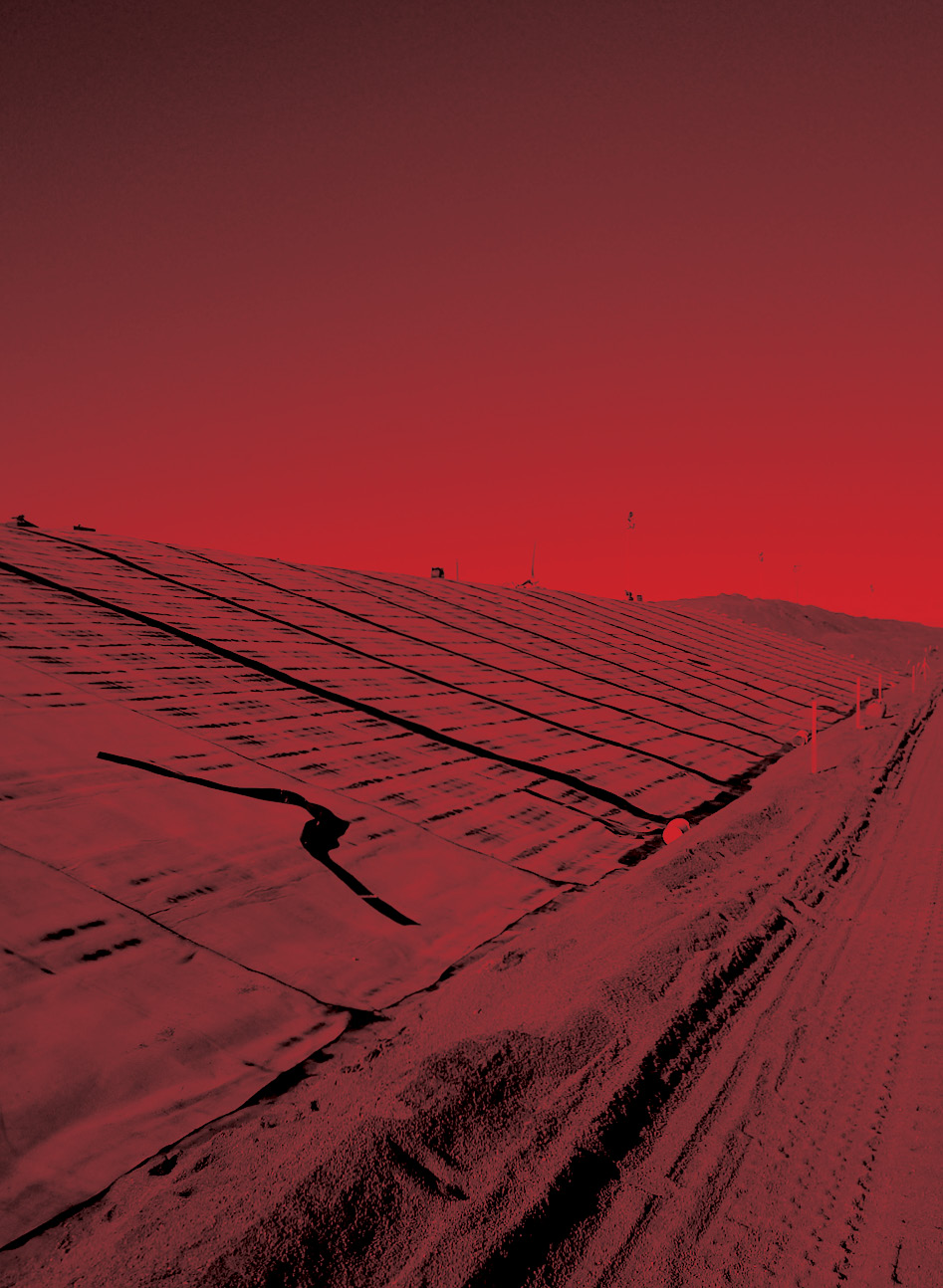

P.H. Tech works with all players in the industry to take up the great challenge of energy efficiency.

Every five years, Energy Star raises the bar by asking construction companies to improve their energy performances.

“There’s been a lot of changes over the

last 20 years. It’s major in the industry!

Of course, our products have to meet

these requirements.”

P.H. Tech is also preparing to launch a new window platform featuring thicker glass, allowing the integration of more insulating layers of air, for improved thermal performance. “This requires us to review all of our products.”

Also, by 2030, the Government of Canada wants windows to perform significantly better in terms of energy efficiency.

From a technological perspective, the industry does not yet know how it will meet this requirement.

There is still some R&D to be done, but we’ll get there!

All around the same table

Teamwork is the the key to achieving government targets. Caroline has been a member of the board of directors of the Association de vitrerie et fenestration du Québec (AVFQ) for a dozen years. This cooperation with other companies is essential.

We could be in competition, but we have common interests.

When the government wants to set new standards, members of the association discuss them.

“We work together and keep the industry players involved. All these discussions are important.”

All players are interdependent and must make a concerted effort. For example, advances in the glass industry have a major impact on the results chain, as glass occupies the largest surface area of the product.

“There are laboratories that simulate energy performance. We work with them on designs. We send them products and they give

us feedback.”

We need everyone to improve, otherwise we won’t be able to reach the targets.

Solution

The pleasure of performing

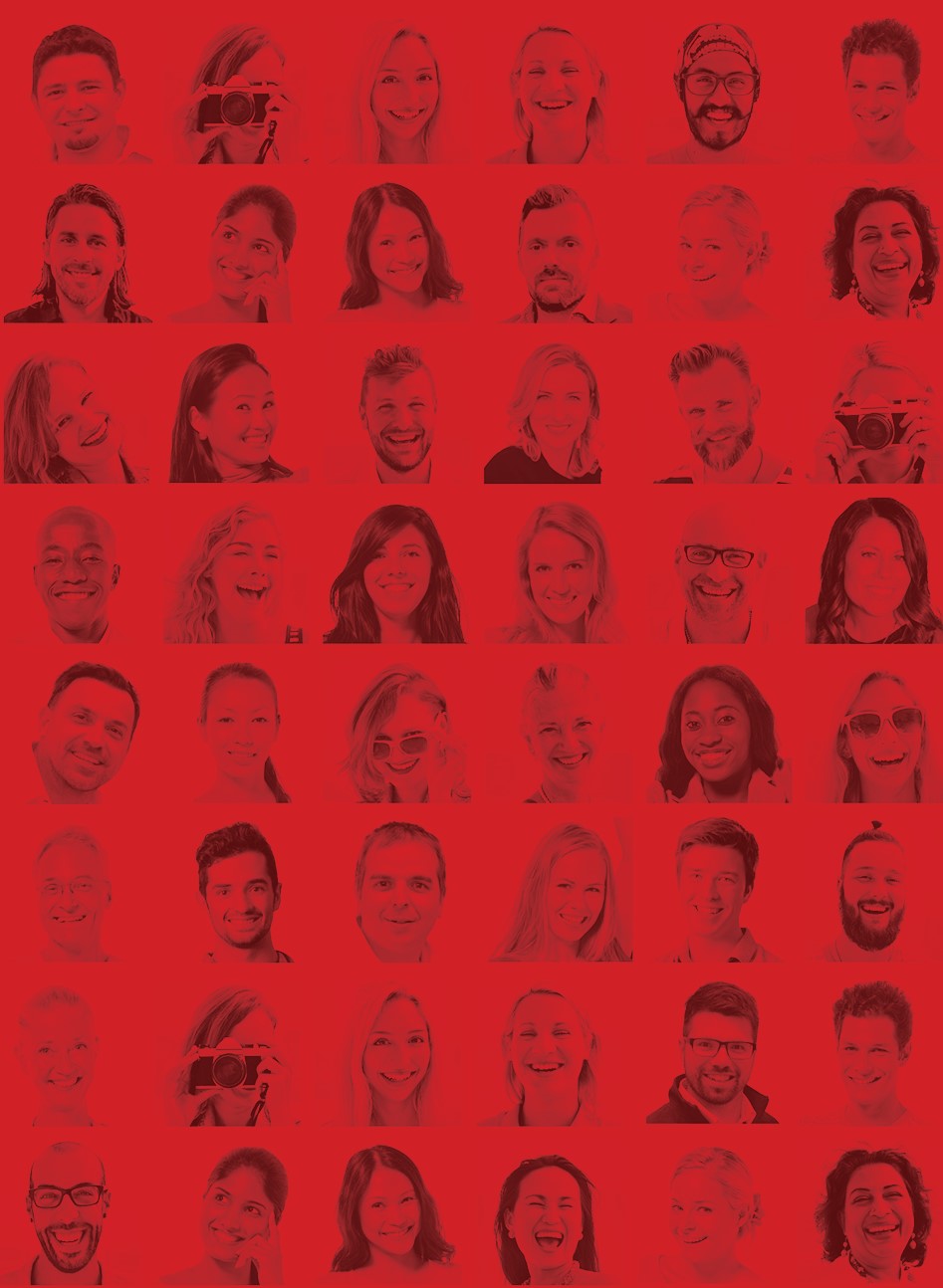

The essential ingredient for achieving such results: engaged employees who are happy to go to work…

The President is very proud to have the trust of some 325 workers across her four plants.

There are employes who have been here for 40 years. When they leave, I tell myself that we’ve managed to support these families for all this time.

Whether new or experienced, all employees deserve to work in a healthy environment, where respect reigns at all time.

“Some people say that it’s obvious, but you have to put it into practice every day. It’s true in our interactions, in our communications, in everything we do.”

Management also makes a point of creating a pleasant work environment, while inspiring people to push back the limits. Designing products that look like ‘simple rectangles’ may seem trivial. But when the team’s energy and vision transform them into the doors and windows of the future, that is the P.H. Tech signature at work…

Comfort

We make sustainable products, we make recyclable products that are energy efficient, we build comfort for users and we have fun doing it!

You need to have fun to attract employees, especially when recruitment is the current challenge in a region like Chaudière-Appalaches, where the unemployment rate is virtually non-existent.

P.H. Tech is a good employer and I find that rewarding!

Workers

Welcome to P.H. Tech

In 2021, the company welcomes its first international workers to fill production positions.

“We have around 13 nationalities throughout the plant.”

Promoting teamwork, the employer goes to great lengths to train these new employees and imbue them with the colours of P.H. Tech. Caroline believes it is important for new employees, whatever their background, to become part of the family.

Alone, it goes fast, but not as far. With a team, you can go much further!

As well as taking care of employees, customer service remains a priority.

“When you do something, you always have to ask yourself whether it’s in the customer’s interests. That’s important!”

Better every day

To become better every day, performance is everyone’s daily responsibility. Staff members are constantly called upon to measure the quality and efficiency of their work.

“If we have not achieved 100% success, we have to ask ourselves how we are going to get there.” In other words, if there is a gap between the desired result and the result achieved, their responsibility is to find solutions to reduce it and continue to improve.

Normally, what we want is to deliver the right product on time. We have to focus on that.

Like never before, every increase in performance is a victory, since the growth of recent years affects production capacity. And even if the demand continues to grow, the shortage of personnel adds to the complexity of the situation.

“Before, we had the equipment and all we had to do was hire workers. Right now, this is our main challenge.”

Behind the scenes...

Passionate about development

Caroline Dallaire

President of P.H. Tech

Caroline Dallaire feels like a fish in water at P.H. Tech. When she joins the company founded by her father and uncle, toward the end of her university studies in industrial engineering, she is stimulated by the multitude of projects to be carried out, supported by an enthusiastic team.

Since 2015, she has assumed the role of president, a position in which she is responsible for the overall management of the company.

“My role is to ensure thar we’re heading in the right direction, that we have the right players and the right systems to get there.”

Passionate about product development, she continues to be involved in R&D and is always in contact with clients.

“This relationship remains important!”

Well surrounded for the next step

In the summer of 2022, P.H. Tech was bought out by management, with the backing of Banque Nationale Private investments and Desjardins Capital. Caroline Dallaire is delighted to count on a new management team that is now a shareholder.

The President now sits on the executive committee with her new shareholders: Director of Sales Stephen Bronson, Director of Canadian Operations Normand Roberge, Director of U.S. Operations Michael Andrade, and Director of Finance Claudia Lapointe.

It a good mix of skills. It’s fun to have a management team that is committed and confident in the future.

Because P.H. Tech has experienced very strong growth in recent years, management’s concern is to stabilize activities and establish a game plan based on the new objectives.

“We are reviewing the organization to make sure we have the team to take the next step, that we have the tools we need and that we can continue our mission.”

Team

An outline of the future...

The passion is still burning!

Driven by the same passion and persistence that have brought them success, the new management team is preparing to open a window on a host of business opportunities.

“There are still several of things to put in place. The pandemic brought its share of challenges. We learned a lot and we need to strengthen our methods and systems.”

Future plans will certainly include recruiting and training new employees to increase production capacity and meet the explosion in demand, while continuing to take care of Canadian and American clients who are at the heart of the company.

Developing a new business contact can take two to three years before a contract is signed. Caroline is well aware of this and knows that patience pays off, since relationships last.

We don’t usually lose customers. Once they’re here, they don’t leave.

At P.H. Tech, taking the time to do things the right way has always paid off in the end, and the pleasure of doing it wholeheartedly remains the greatest driving force of all. Such is the recipe for success at P.H. Tech, which has been going strong for 60 years…

You have to be very persistent. You have to be passionate. You have to believe it, to really believe it. You must surround yourself with

a good team.

“To be successful, you need leaders in the right positions. And you have to have fun, I think. Without fun, it’s difficult because it’s a lot of work. You really have to enjoy it!”

Success

PH Tech – English

8650, boul. Guillaume-Couture

Lévis (Québec) G6V 9G9

418 833-3231

phtech.caPublishing Director: Audrey Dallaire

Author: Caroline Lepage

Translator: Frédérick Poulin

Graphic designer: Liliane Racine

Proofreader: Céline Chabot

Read also

in the same sector

of activity

Construction, Fabrication

À venir

Qualtech

Fabrication

Capitale-Nationale

COEX

Architecture et aménagement, Construction, Services

Montréal

Groupe Pylium

Construction

Saguenay-Lac-Saint-Jean

Maître Constructeur Saint-Jacques

Architecture et aménagement, Construction

A4 Architecture

Architecture et aménagement, Construction, Services

Outaouais

FC géosynthétiques

Construction

Chaudière-Appalaches

Elema

Construction, Ingénierie

Montréal

Mécanique industrielle AMNC

Construction, Ingénierie, Installation mécanique

Lanaudière

Groupe Cambli – English

Fabrication

Montérégie

Elema – English

Construction, Ingénierie

Montréal

AGT Robotics – English

Fabrication

Mauricie

Tremcar – English

Fabrication

Montérégie

Norda Stelo – English version

Construction, Ingénierie

Capitale-Nationale

Paber Aluminium – English

Fabrication

Chaudière-Appalaches

Jambette – English

Fabrication

Chaudière-Appalaches

EcoloPharm – English

Fabrication

Montérégie

Archex (EN)

Fabrication, Kiosques d'expositions

Montréal

Groupe Diamantex

Construction

Capitale-Nationale

GBI

Ingénierie

Capitale-Nationale, Lanaudière, Laurentides, Montérégie, Montréal

Entreprise Courtval

Fabrication

Estrie

Norda Stelo

Construction, Ingénierie

Capitale-Nationale

Industries Mailhot

Fabrication

Lanaudière

Elecso

Construction

Montérégie

Habitalogik

Construction

Saguenay-Lac-Saint-Jean

Groupe Module Construction

Construction

Montréal

Conceptromec

Fabrication

Estrie

Construction & Expertise PG

Construction

Montérégie

Groupe Cambli

Fabrication

Montérégie

PH Tech

Construction, Fabrication

Chaudière-Appalaches

Archex

Fabrication, Kiosques d'expositions

Montréal

MÉTATUBE

Fabrication

Saguenay-Lac-Saint-Jean

J.M. Demers

Construction

Chaudière-Appalaches

Infrastructel

Ingénierie

Montérégie

Metalium

Fabrication

Montérégie

CEVICO

Construction

Saguenay-Lac-Saint-Jean

Tremcar

Fabrication

Montérégie

Précision SF Tech

Fabrication

Lanaudière

EcoloPharm

Fabrication

Montérégie

AGT Robotique

Fabrication

Mauricie

Les Industries Rainville

Fabrication

Montérégie

LABPLAS

Fabrication

Montérégie

Shalwin

Fabrication

Mauricie

Produits Métalliques Bussières

Fabrication

Chaudière-Appalaches

RG Solution

Construction, Fabrication

Estrie

Beaucinox

Fabrication

Chaudière-Appalaches

Metalilux

Fabrication

Laurentides

MegLab

Fabrication

Abitibi-Témiscamingue

Tiges 4 saisons

Fabrication

Centre-du-Québec

Techni-Arp

Construction, Services

Capitale-Nationale

Paber Aluminium

Fabrication

Chaudière-Appalaches

MMS laser

Fabrication

Centre-du-Québec

Recyc PHP

Économie sociale, Fabrication

Centre-du-Québec

Les Branchés Lunetterie

Commerce de gros et détail, Fabrication, Services

Laurentides

Jambette

Fabrication

Chaudière-Appalaches

Distillerie 3 lacs

Fabrication

Montérégie

Enviro Confort

Construction

Chaudière-Appalaches

V Création

Fabrication

Laurentides

Gabion Express

Construction

Chaudière-Appalaches

Ferreol

Fabrication

Capitale-Nationale

Les Industries Phomère

Fabrication

Capitale-Nationale

Équipement St-Germain

Construction, Transport & Entreposage

Capitale-Nationale, Montérégie

Read also

in the same

region

Chaudière-Appalaches

FC géosynthétiques

Construction

Chaudière-Appalaches

Everest Automation – English

Services

Chaudière-Appalaches

Paber Aluminium – English

Fabrication

Chaudière-Appalaches

Jambette – English

Fabrication

Chaudière-Appalaches

Everest Automation

Services

Chaudière-Appalaches

PH Tech

Construction, Fabrication

Chaudière-Appalaches

Firebarns

Alimentation

Chaudière-Appalaches

J.M. Demers

Construction

Chaudière-Appalaches

Produits Métalliques Bussières

Fabrication

Chaudière-Appalaches

Beaucinox

Fabrication

Chaudière-Appalaches

Paber Aluminium

Fabrication

Chaudière-Appalaches

BEAUCE SPORTS

Commerce de gros et détail

Chaudière-Appalaches

Jambette

Fabrication

Chaudière-Appalaches

Mobile-Punch

Communication, technologie & Technologie de l'information

Chaudière-Appalaches

Enviro Confort

Construction

Chaudière-Appalaches

Gabion Express

Construction

Chaudière-Appalaches