Daniel Tremblay

Fabrication

Montérégie

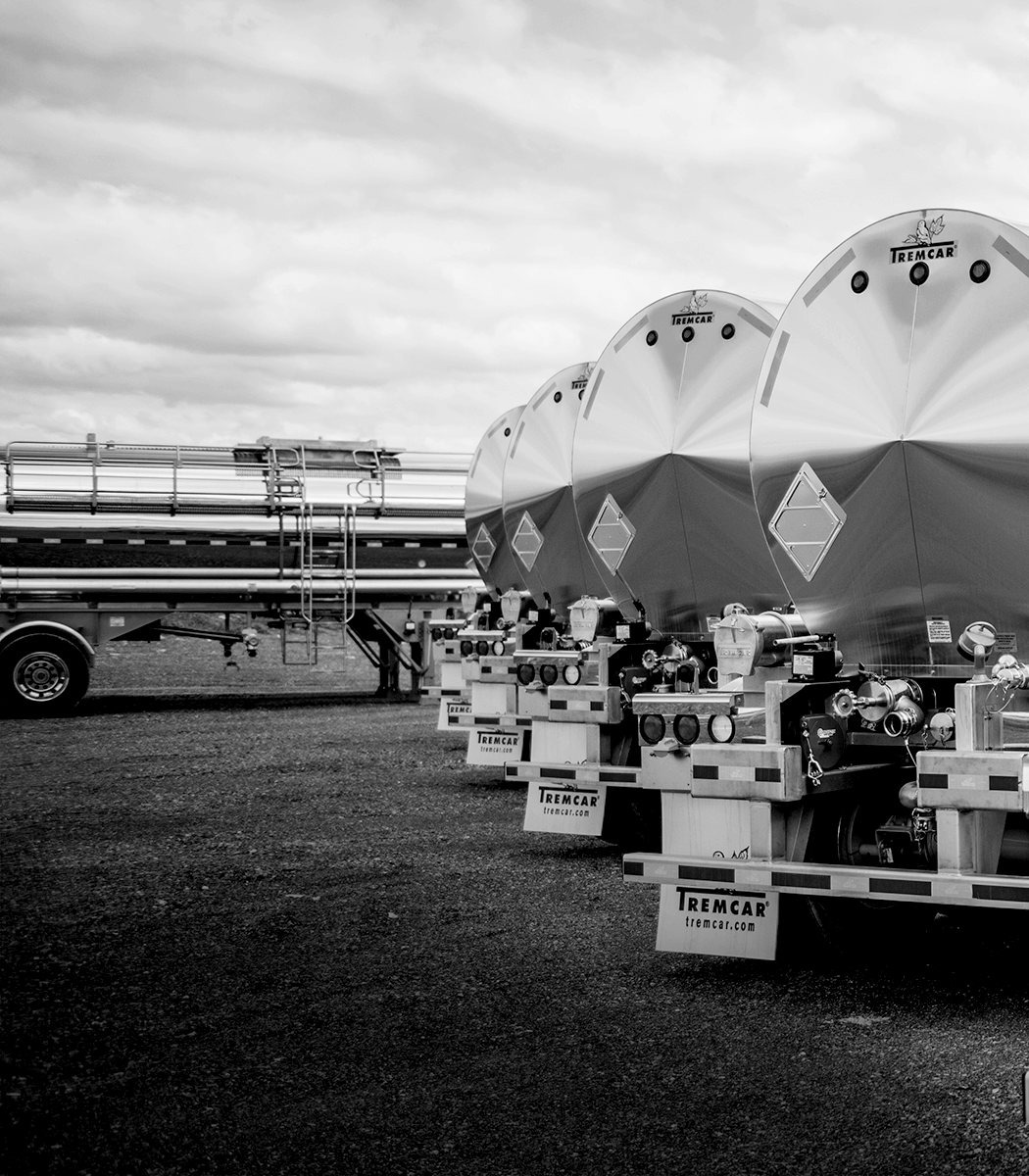

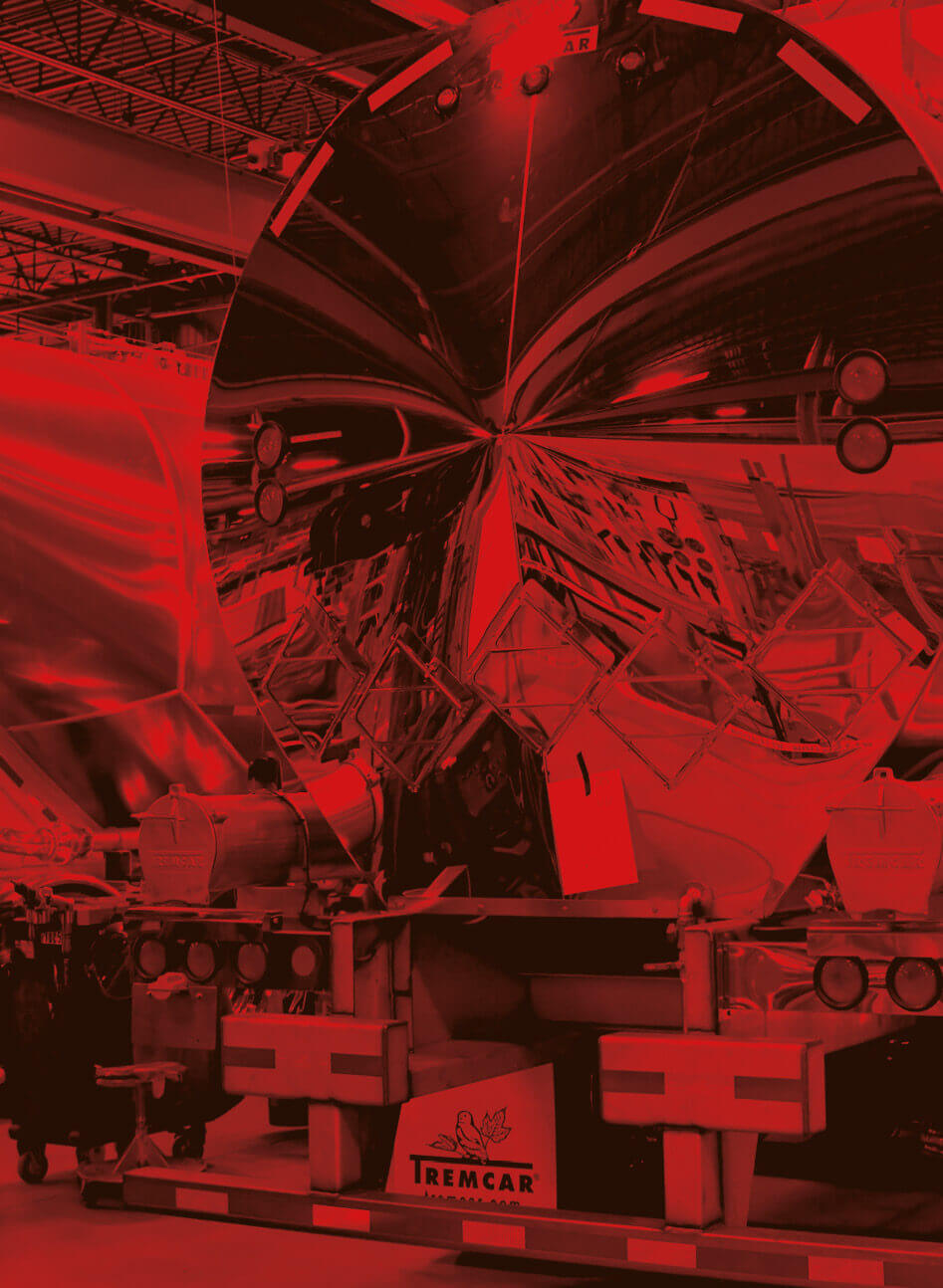

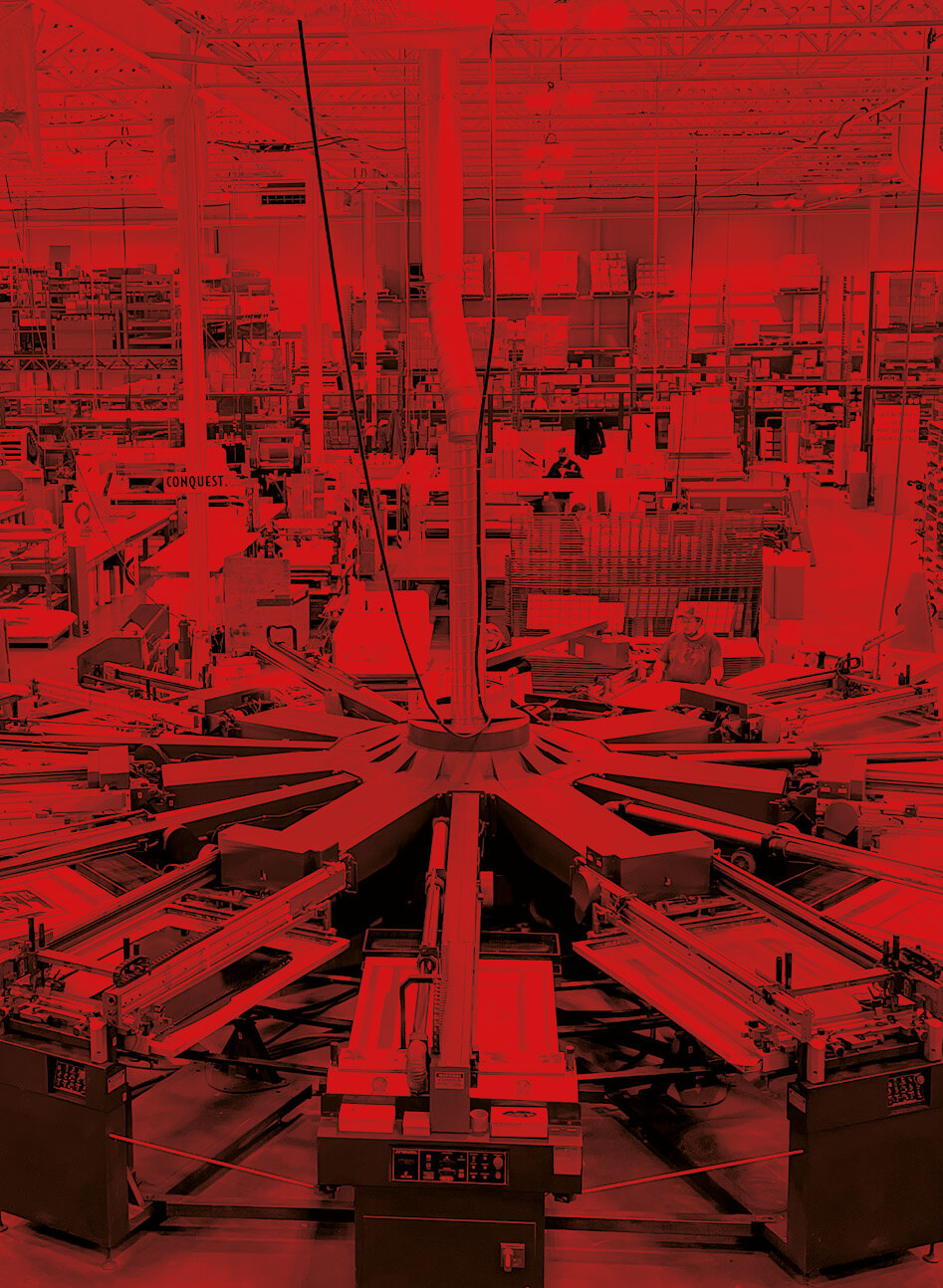

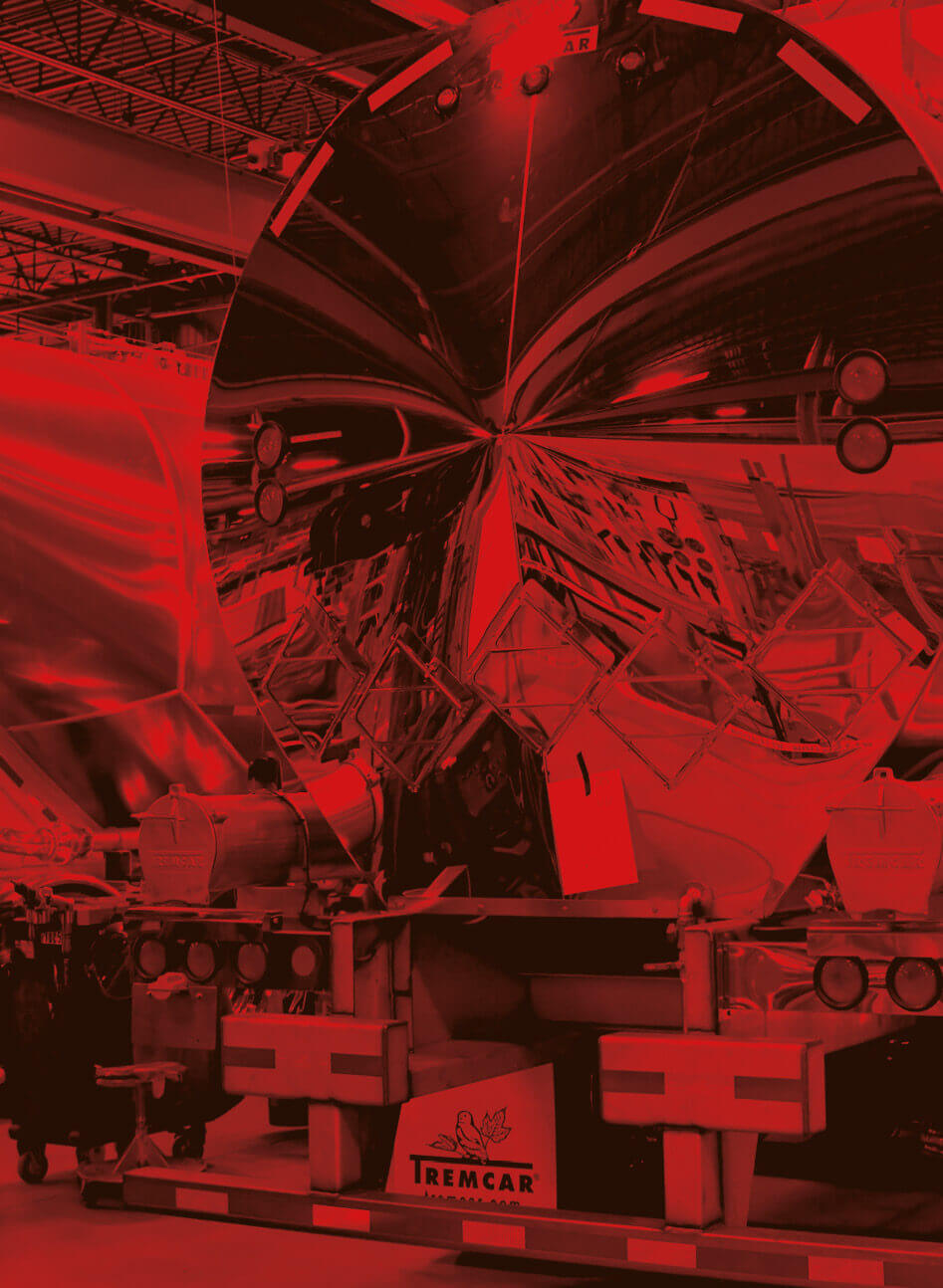

Founded in 1962, Tremcar is one of the four largest manufacturers of tank trailers in North America. The company’s strength lies in the diversity of its products, and in its ability to custom-design tanks for the 5,000 customers it serves. Despite the ups and downs of the economy, this family business, led by Daniel Tremblay, never ceases to reach new heights. Daniel and his team’s approach to re-engineering is at the heart of the company’s history and success.

Share on social medias

Share on social medias

Foreword...

Eyes on the road and both hands on the wheel

How can we do so much better as a team? This question obsesses Daniel Tremblay. The goal is to improve productivity by finding ways to redesign products and rethink manufacturing processes, while working hand in hand with engineering, purchasing and production.

Now that’s my cup of tea.

A man of ambition and a trained economist, Daniel is capable of turning any disastrous situation to his advantage. Having been with Tremcar for 30 years, he has witnessed several recessions that the transportation industry has not been immune to.

When the economy starts crumbling, it’s a wake- up call. It motivates me to get up in the morning and fight on the front lines.

This business man does not shy away from challenges. “I’m a revolutionary — a warrior at heart.” He knows how to mobilize teams through his positive leadership and when a problem arises, he does not hesitate to solve it with both hands on firmly on the wheel.

Leadership

Dealing with chaos

Daniel is a strong proponent of constant evolution. He believes he is the right person to bring projects to fruition in the most chaotic of circumstances. “After six months, I have to hand the file over to someone else.” He does not mind sticking his nose out wherever there is a problem! In fact, he has even turned around a number of financially troubled companies by acquiring them.

I just love trouble!

He takes great pride in contributing to the bulk transportation industry though Tremcar innovations. His philosophy is not to create wealth, but rather to pass on the knowledge to better the industry. “When we invest to innovate, we invest in driver safety and we try to facilite their job. “When customers buy tanks from us they can be sure their safety is our priority”

The genesis...

Ambitions that go a long way

Tremcar’s rise to success is due in no small part to the boldness of Daniel Tremblay, who joins his father’s company in 1992.

The company was first established 60 years ago by the Tougas brothers, two welders who capitalized on the booming milk industry by marketing tanks for milk transportation on trucks.

When the brothers are looking to sell the company in the late 1980s, Jacques Tremblay, who was an entrepreneur in the concrete industry at the time, sees this acquisition as a way to diversify his business. Soon thereafter, he calls on his son Daniel to come and help him in the production department, as he too had worked in the concrete industry during his youth.

It was boring me to death!

Always having had a passion for mechanics, Daniel jumps on the opportunity, even though he is preparing to leave Quebec

to do a master’s degree at the University of British Columbia.

I walked in the next morning and I never left!

Daniel starts working for Tremcar as a foreman in 1992 before becoming director of production. With the help of its 27 employees, Tremcar produces three tanks per month. But Daniel soon has much bigger plans for the family business.

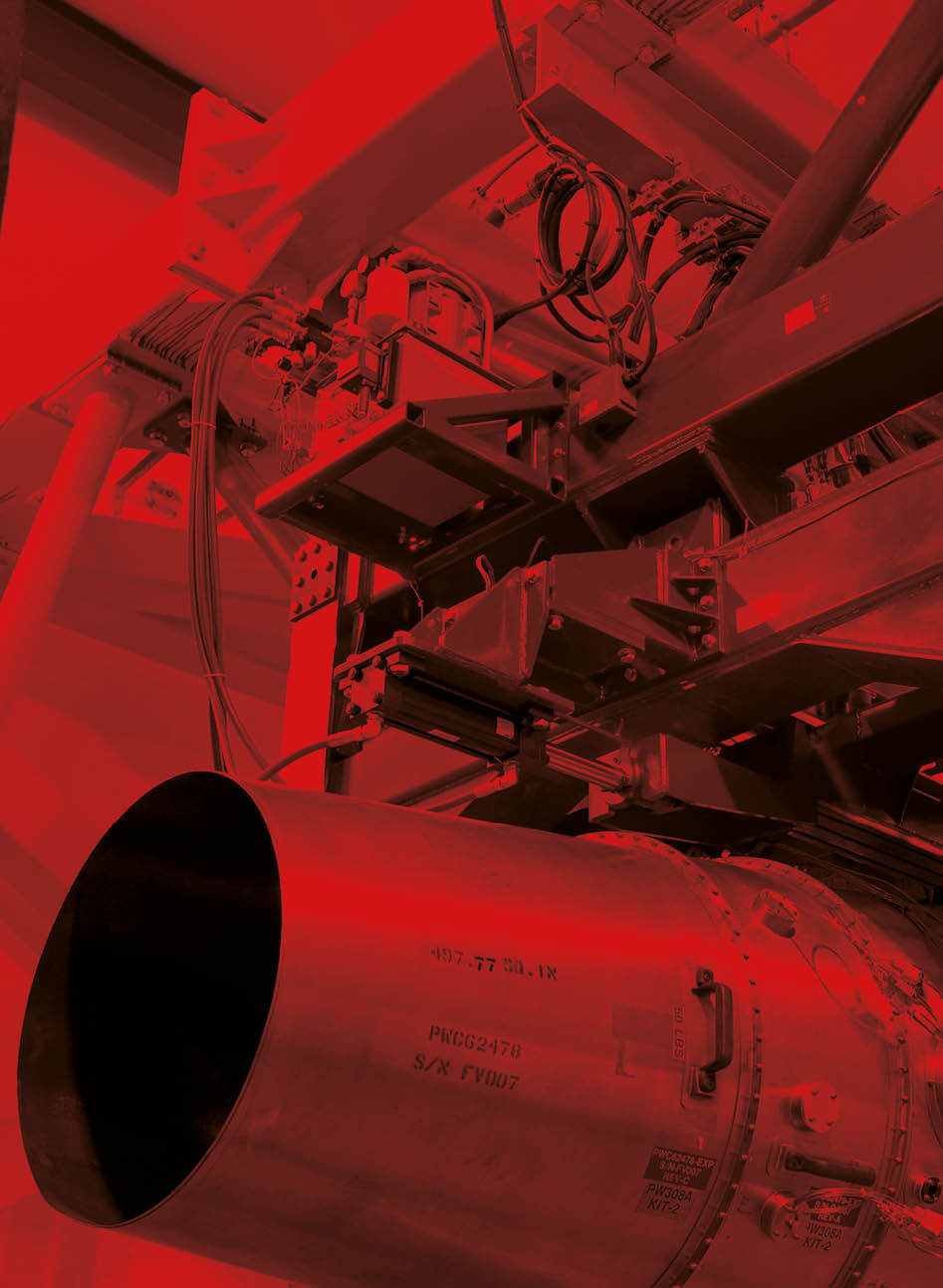

That same year, Tremcar obtains the American ASME standard, which allows the manufacturing stainless steel DOT 407 bulk chemical tanks. Tremcar is then able to diversify its offering, providing customers with tanks tailored to their needs. “There is a huge market in the U.S. and Canada for the transportation of chemicals products.”

Their tanks can be used for the transportation of all sorts of products: clothing disinfectants, cutting lubricants, pulp and paper bleachers, paint and latex, etc.

Boldness

Dr. André Gamache award, 2022

Rollercoaster years

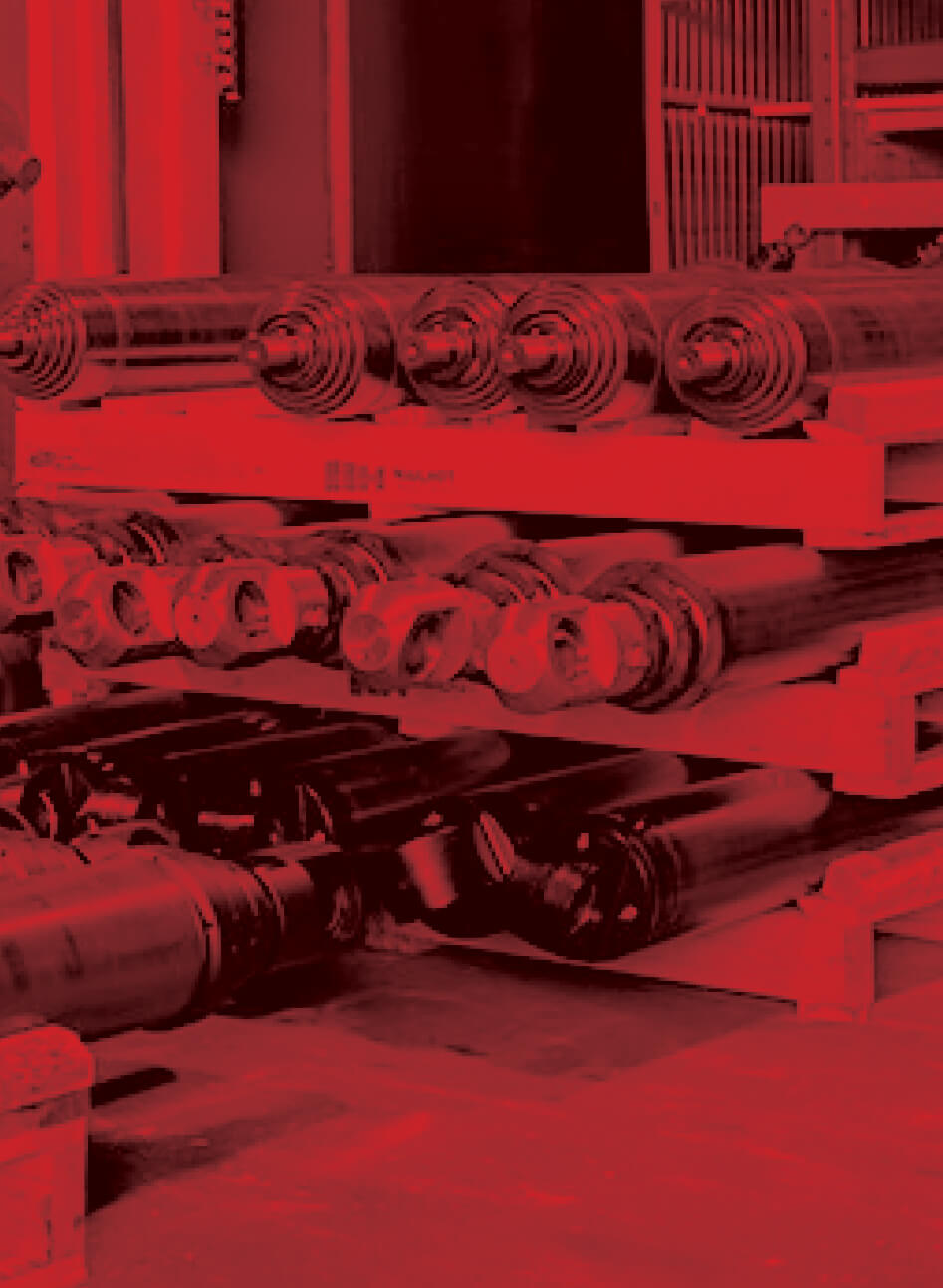

Besides building milk tankers which were gaining ground in the U.S., Tremcar diversifies its production with tanks designed to

carry bulk chemical products in 1995. “It was going full steam ahead.” The production output rises from three to twenty units a month.

I had grown the business sevenfold in three years!

Production picks up steady momentum. In 1996, Daniel’s father sells his concrete company to become involved in sales and finance. Two strengths that complement Daniel’s own, who is more focused on production and operations. With plants in Champlain (New York), Drummondville, and Saint-Jean-sur -Richelieu (head office), Daniel takes the operations department of all three plants under his wing.

That same year, the Canada Transportation Act is amended, forcing companies to have stronger, safer tanks. But such tanks are heavier and more expensive. With a maximum weight to be observed on the roads, carriers cannot ship as many products as they did before.

Everybody anticipated the new legislation. That’s why the business was running at full speed two years before the law came into effect.

But the market comes crashing down. As a result, Tremcar has just eight tanks left in its order book.

I thought about laying off everybody. We were heading straight for disaster.

However, fortune shines on Daniel in 1997 as he lands a major contract that enables the company to survive until 1999. During this time, Tremcar begins producing aluminum tanks for transporting dry bulk products such as cement powder, flour, sand and lime.

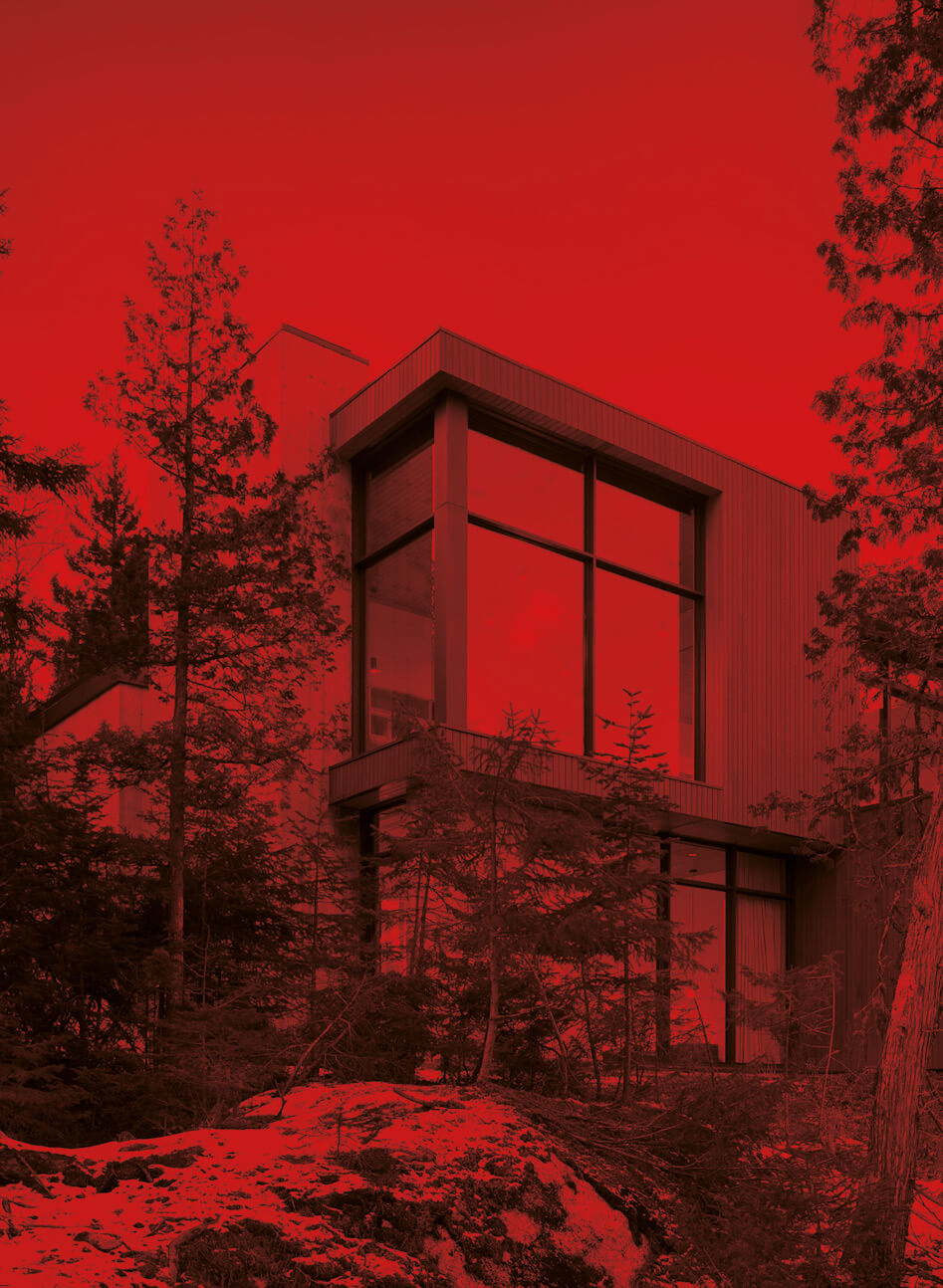

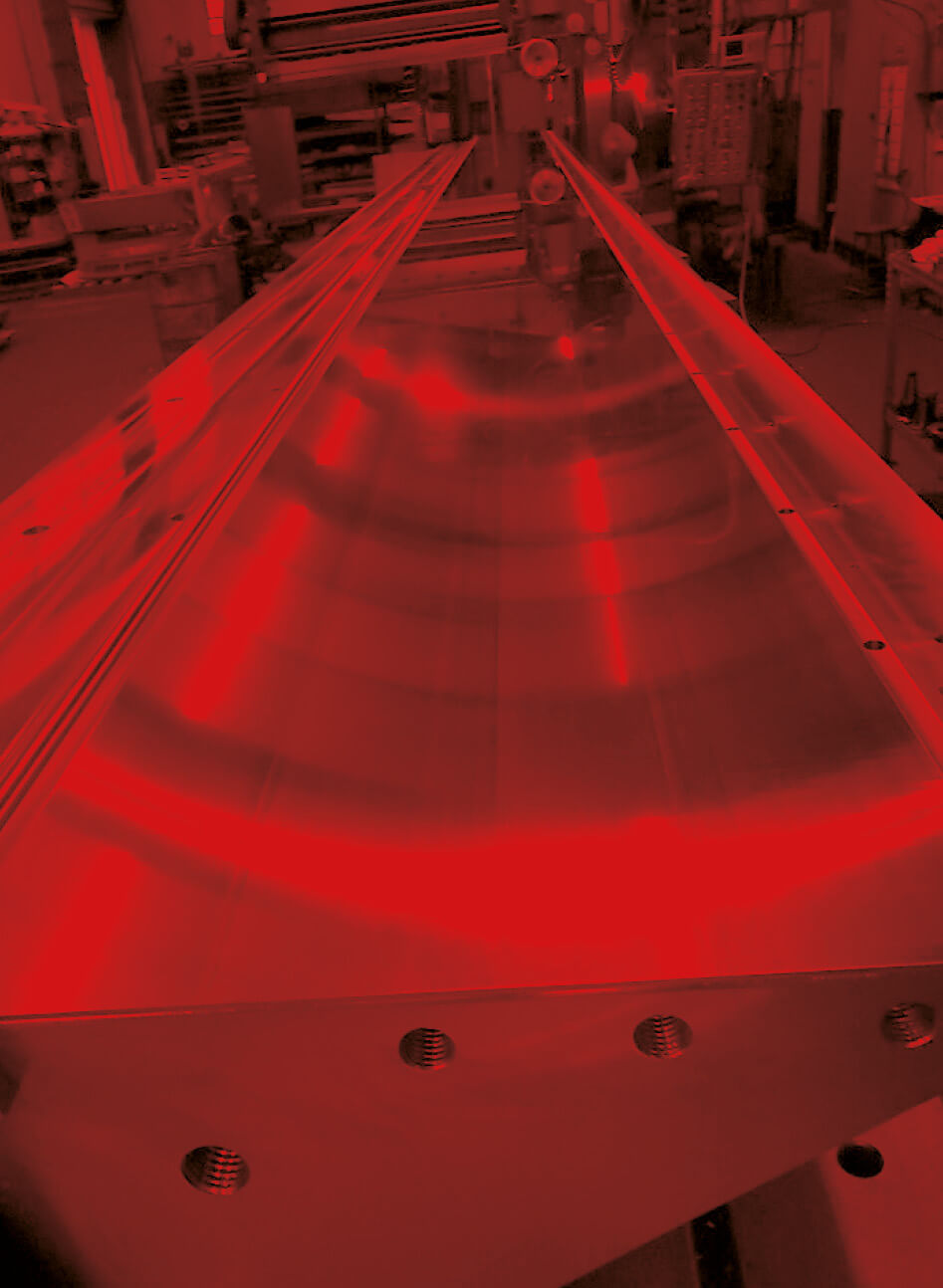

With production becoming increasingly diversified, the Tremblay family transfers its assets and installations from Drummondville to Saint-Césaire, in 2002. The move optimizes operations by bringing the plants closer together. The Saint-Césaire plant expands into the production of aluminum trailers for dry goods. Sales in the U.S. increase, and Tremcar becomes a major player in the market. Two years later, Tremcar opens a head office in Strasburg, Ohio.

A plant of INTERNATIONAL calibre

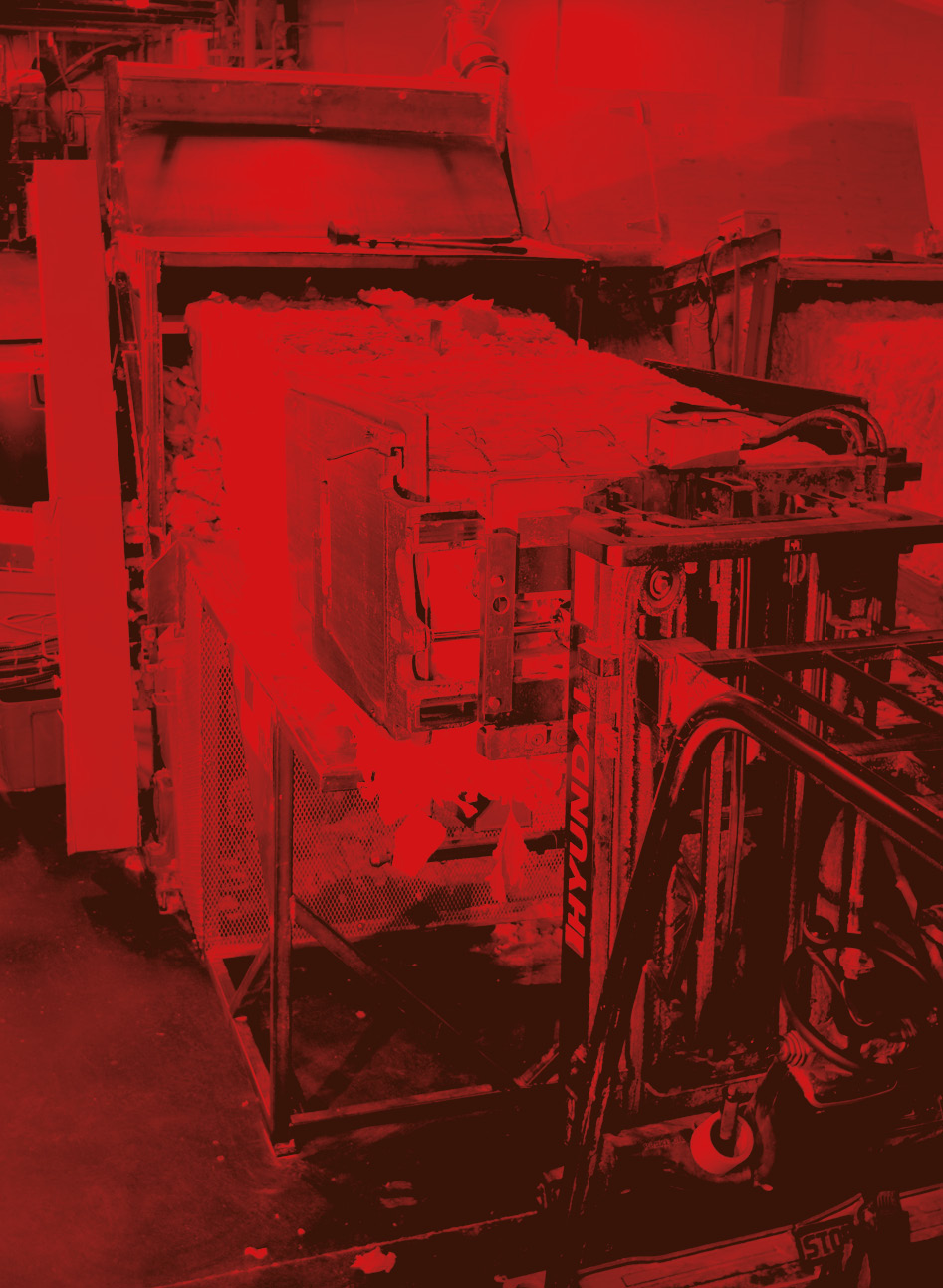

With its low ceilings and lack of space, the Saint-Jean-sur-Richelieu plant is completely outdated and no longer meets the needs of Tremcar’s, who is growing fast. Over time, the plant would undergo eight expansions.

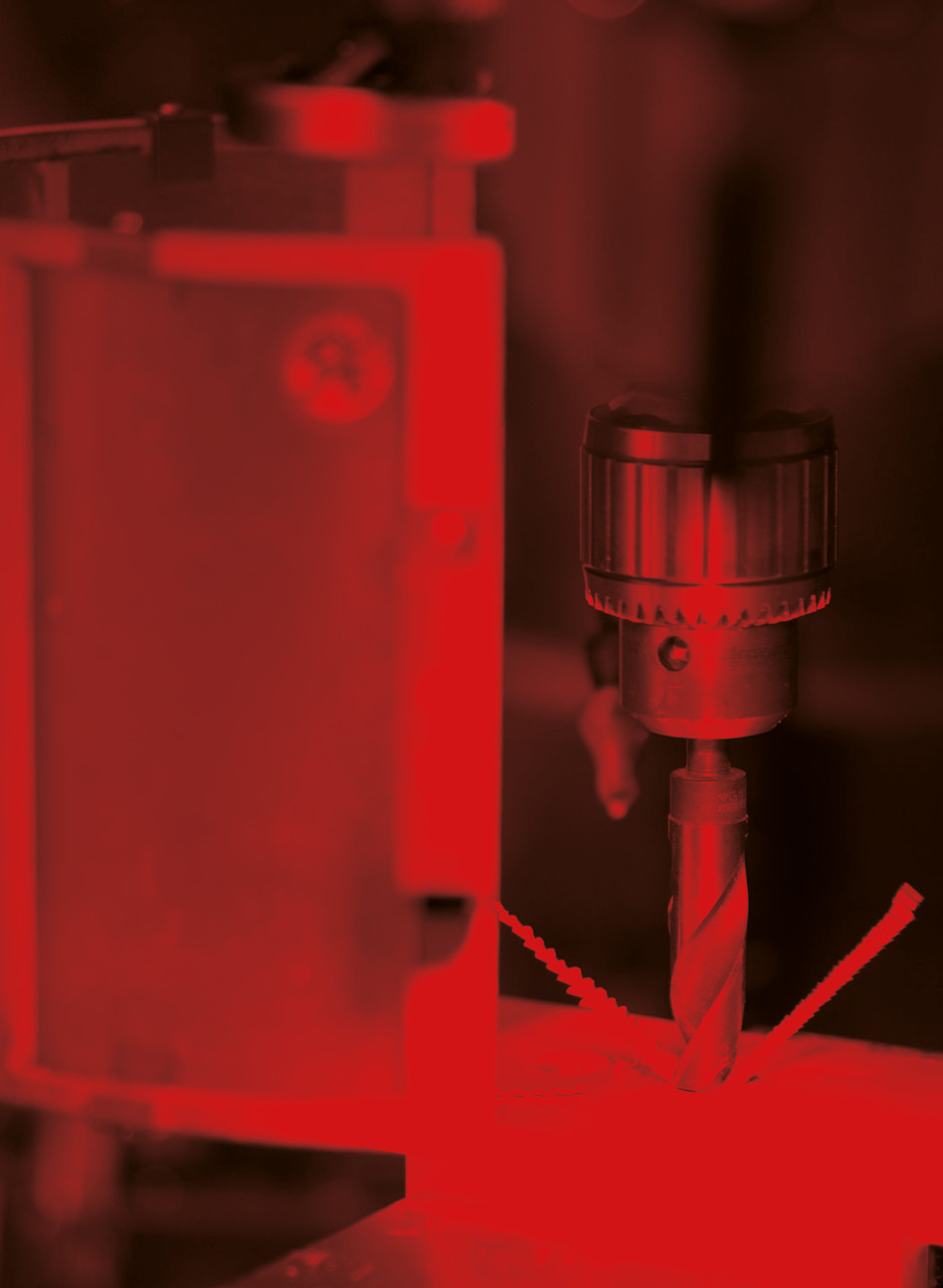

In 2005, the Saint-Jean-sur-Richelieu head office, which focuses on stainless steel tanks, moves to the industrial park. At the same time, lean manufacturing is completely reassessed; and Daniel changes the ways things are done. A system of quality control, inventory control, and production management is implemented. The production time for a tank is cut from 22 days to six. “With the same money and the same inventory, we were making three times as many tank trailers!”

Now THAT put us on the map!

With this new, updated, plant, Daniel, who is acting as Vice-President of Operations, is appointed President, while his father is in charge of special projects for certain acquisitions, such as the one in Toronto.

Our strengths complement each other.

Part of the evolution

In 2022, with nearly 60 years of experience, Tremcar is a key player in the evolution of the transportation industry in America.

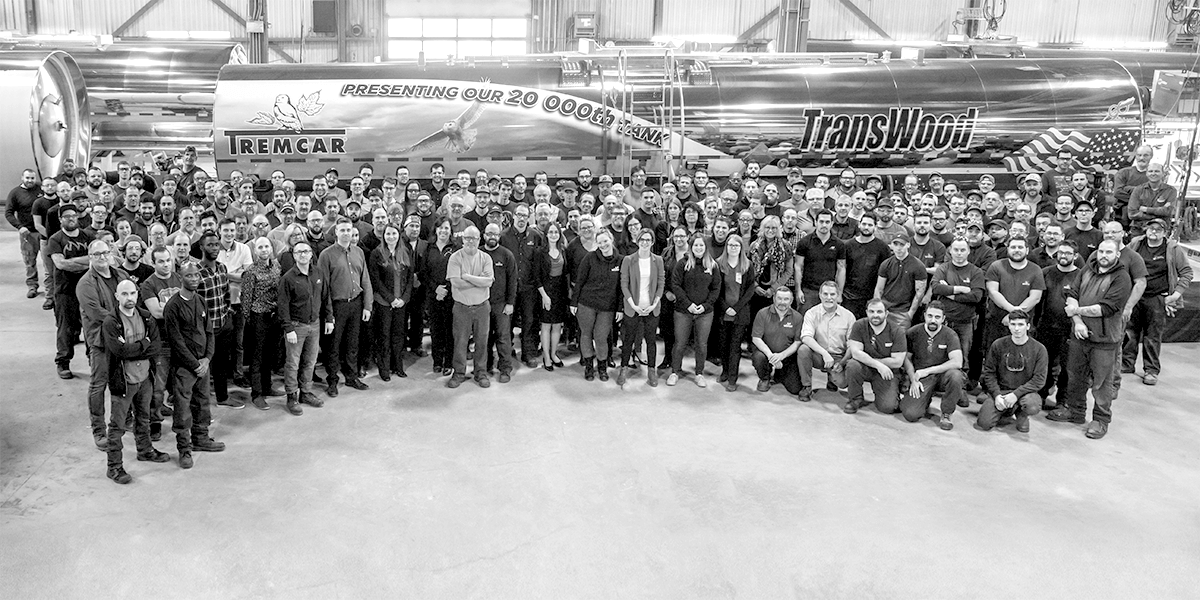

Since taking over as President, Daniel leads his team masterfully. Between 2006 and 2014, Tremcar acquires many companies in Toronto, London (Ontario) and Boston (Massachusetts), enabling it diversify its products and meet the needs of a growing clientele. In 2020, production rates reach 100 tanks a month.

In addition to North America, the market extends to South America and the Caribbean. These markets are open to them as they mainly transport oil, but also products for the mines. “We make all the tanks for transporting dry products for mines in Peru and Chile.”

And although North Americans are tending to reduce their milk consumption, the dairy industry is still growing in some parts of the world. Milk is a luxury product, just as it was for USA & Canada 50 years ago.

Countries are not all at the same point in their eating habits cycle.

Daniel thus remains on the lookout for market fluctuations that could turn into business opportunities for Tremcar.

Vision and values...

Resilience in the face of economic uncertainty

Tremcar is recognized for its customized tank designs, which enables it to diversify its market share and protect itself from the impacts of economic cycles. Nevertheless, Daniel experiences a number of setbacks when the economy is struggling.

In 1998, Daniel opens a plant in Champlain, New York. For 18 months, he focuses his efforts on making it functional and efficient. Only two years later, he has to close it when Canada goes into recession.

We barely had time to make some profit with it and we shut it down.

This kind of situation motivates Daniel, who has the perfect temperament to take on any challenge that the economy throws his way.

In march 2000, oil prices soar and Tremcar loses around 50% of its sales. The order book stalls completely. “I knew we were heading into a serious recession.”

Daniel has to make the decision that no entrepreneur likes to make. In a three-month period, he lays off his employees, sells the equipment and liquidates the inventory. The same thing happens at the Drummondville plant.

I had 85 employees, I got down to 7.

Economy

Decision

Another major storm shakes Tremcar’s foundation in 2008, as a banking and financial crisis emerges. Customers no longer have the money to place orders. “They were telling me: Daniel, the business is there, but I can’t get financing.”

But ups and downs of the economy spur Daiel on, and he shows resilience in the face of adversity. He manages to find ways to cut costs and reorganize his production plants.

We’ve always been able to get through it.

This is exactly what happens in 2014, when the oil crisis begins and the price per barrel drops from $125 to $25. All investments

in Western Canada come to a screeching halt. Royalties and exorbitant taxes are also introduced. “All the oil companies stopped investing in Canada overnight.”

Daniel once again makes a heart-wrenching decision for the benefit of the company. The Toronto plant that manufactures fuel oil tanks for Western Canada has to be closed. Production is transferred over to Saint-Jean- sur-Richelieu and Saint-Césaire, and both plants are expanded.

I like to find solutions to get us out of trouble.

Within four months, Tremcar’s main competitor goes bankrupt. The diversity of products makes management challenging for Tremcar, but it is also safer, as the company is established in all sectors.

Thanks to this, we’re able to compensate for and eliminate some of the risks.

Promoting knowledge synergy

Réorganisation

Daniel’s career is filled with hundreds of examples of perseverance and determination. He is especially proud, however, of what

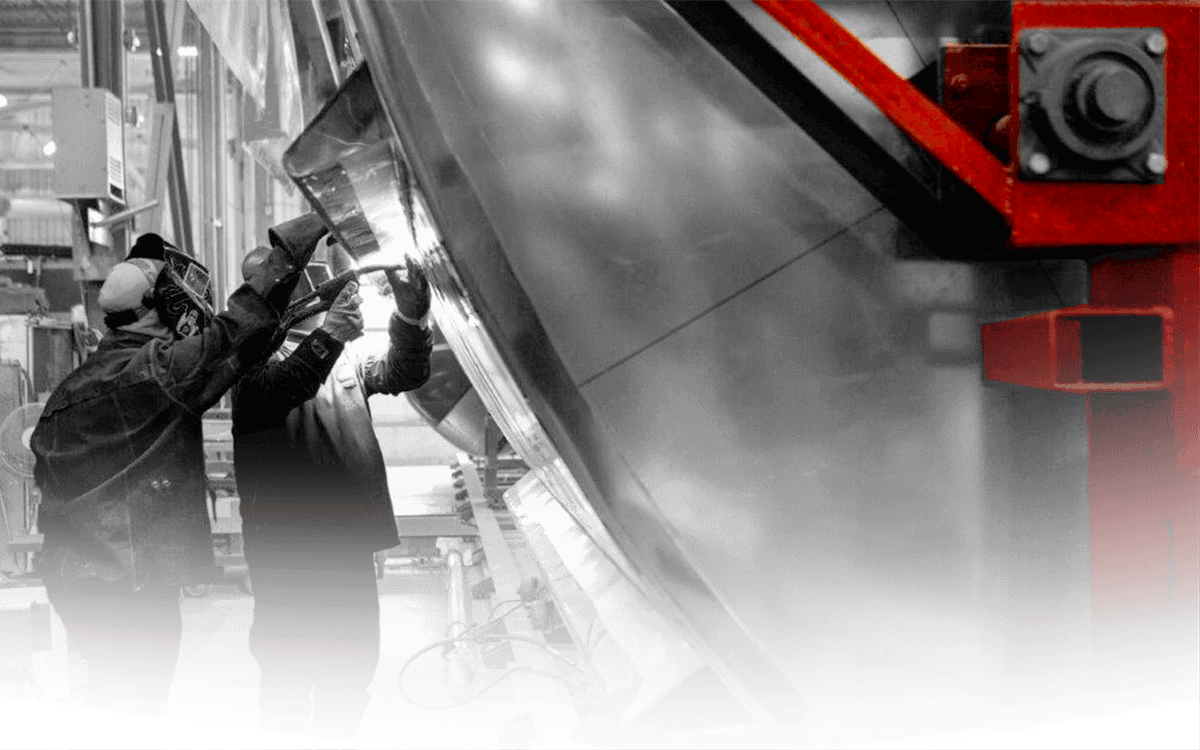

he accomplishes with the bitumen tankers, which are used to transport liquid asphalt.

For ten years, this division of Tremcar was unprofitable. The service is lacking both in terms of product quality and manufacturing efficiency. Daniel decides to take the matter into his own hands. He convenes a team to the Saint-Césaire and Saint-Jean-sur- Richelieu plants to break the deadlock.

We went over the tank piece by piece, process by process.

Today, this tank is sold in the U.S., Ontario, Quebec and Eastern Canada. “That product is a real team success.”

As of 2023, Tremcar has a total of ten plants and service centers and has 525 employees.

The whole management and way of moving forward is totally different from when we had 27 employees back in 1992.

Daniel is able to see the skills in each member of his team and get them to develop to their full potential. “My strength is bringing everyone together at the peak of their capacity.”

Talking the talk and walking the walk

Daniel loves people, their stories and their journeys. When he launches a welding school in 2014, he has no idea of the impact he will have on the lives of his students.

Involved on the Saint-Jean-sur-Richelieu economic development comity, he realizes that Quebec is experiencing the beginnings of a labour shortage. Vocational schools have barely ten students in welding. “It just didn’t make sense for the region. We have dozens of companies that need welders.”

He quickly makes the link between schooling and the lack of income. When students

go to school, they do not earn a salary for

18 months, which is the time needed to complete the welding course.

“If they don’t live with their parents, they’re done for.” They will then have to make do with working for minimum wage in a grocery or convenient store.

It’s as if society had given up on these people.

Aware that not everyone can find themselves in such circumstances, Daniel takes matters into his own hands. He comes up with the idea of paying students during their welding program and guaranteeing them a permanent job afterwards. He approaches the Quebec government, but the process drags on and ends up nowhere. Daniel loses patience and moves forward on his own.

Through his own resources, he hires a teacher from the vocational school in Saint-Jean-sur-Richelieu to give a welding course at Tremcar.

“We decided to pay our people $1 above the minimum wage.”

In 2018, Daniel runs a test with six students in the factory. While a welding course usually takes 18 months to complete, Daniel has the nerve to ask the teacher to cut it down to four. “The teacher told me: That’s insane!” Nevertheless, Daniel is adamant. All the superfluous material is removed from the program.

The tour de force is a success. Daniel acquires a building in Saint-Césaire, in which he installs 20 welding machines. Three months later, the courses begin.

As of 2023, the school has more than 60 graduates across seven cohorts. “We pay $23 an hour to study, and $27 afterwards.”

People first and foremost

In addition to addressing the labour shortage in the factories, Daniel is lifting some young people out from poverty by improving their quality of life.

“There are people behind all of this.”

At the graduation ceremony, some parents cry because they are so proud to see their child succeed. Some even tell Daniel how much the program has changed their lives. “There are students who have never had a diploma before in their lives. Most of them didn’t graduate from high school.”

On a purely human level, it’s very gratifying.

Today, the diploma (STC) is recognized by the government. Daniel is proud to have persevered in realizing his idea.

Behind the scenes...

The maestro

Daniel Tremblay

President

Daniel is a firm believer that success in business cannot be achieved by just one man. But if a team is essential, so is the leadership of a maestro.

“If you believe in it halfway, you’re missing half of your human capital.”

As president, Daniel believes in his company, but above all he commits himself daily to the projects without waiting for other people to take over. His commitment enables him to pass on his passion to his team. He is also able to take the strengths of each individual and use them in the right way.

“I’m like a conductor – I’m the Kent Nagano of tanks.”

The motivator

Martin Lussier

Vice-President Finance and Operations

Energetic and curious, Martin is a leader who puts employees at the top of his priorities, with the goal of helping them develop and reach new levels. Although his role at Tremcar is demanding, it does not stop him from having fun at work.

“Team spirit is also critical, maybe even more so than on a sports team.”

With a background in accounting and finance from the Université du Québec à Trois- Rivières, Martin hones his skills with training in lean manufacturing and Six Sigma. He has almost 30 years’ experience in accounting as a manager in the sectors of manufacturing, retail and multi-channel industries. He is also focused on process and performance: not only is he motivated to reach targets, but above all to exceed them.

Martin thrives on challenges and tight deadlines drive him to excel.

The loyal one

Éric Archambault

Director of Purchasing

Éric joins Tremcar in 1993 as part of a traineeship in welding and assembly at the Saint-Jean-sur-Richelieu vocational school. He quickly proves his worth and is hired as a welder a year later. He witnesses the company’s many acquisitions, including the Drummondville plant, where he becomes team leader. His skills lead him to work in a service centre in Ontario and to learn English. As Tremcar believes in Eric’s potential, he is offered a job in purchasing in 2000, which motivates him to take part-time courses in purchasing. After three years of study, he obtains his diploma from PMAC (Purchasing Management Association of Canada). A few years later, he is promoted to Director of Purchasing, a position he has now held for over ten years. Rigorous and a good listener, Éric is versatile and is not afraid to get his hands dirty to help his team.

“I adapt to any situation and I try to anticipate the hits.”

The meticulous

Corey Kirk

Chief Engineer

Corey joins Tremcar after graduating from Concordia University in mechanical engineering in 2006. He begins his career

in the sales department and works his way up from product engineer to project manager and supervisor. As Chief Engineer, he is called upon to sit on regulatory and engineering committees both in Canada and in the U.S. With a keen eye for detail and a strong sense of responsibility, he oversees the quality control and warranty department. His analytical approach leads him to optimize solutions in most situations. “I’ve developed the ability to make quick decisions with sometimes incomplete, or even contradictory, information.”

Over the years, Corey has learned the value of communication and managing the human side of business relationships, whether with colleagues, customers, work teams and so on. As a result, he advocates a positive and persevering approach through coaching and mentoring his teammates.

The soldier

Mélanie Dufresne

Director Marketing and Communications

Dynamic and gifted with a sixth sense for understanding people, Mélanie joins Tremcar in 2014 as assistant to the president before becoming Director of Marketing and Communications. With a bachelor’s degree in political science from Concordia University, she is elected municipal councillor for the City of Saint-Jean-sur-Richelieu in 2013. Re-elected for a third term, she continues to serve as councillor and as deputy mayor. Mélanie is a no-nonsense woman: she is not afraid to tell it like it is.

Spontaneous and always ready for action, she sees herself as a front-line soldier who enjoys challenges and bringing joy to people around her.

“There’s so much to do and so little time. For me, everything is important: work, family, community… global well-being, everything!”

An outline of the future...

Investing to stay in the game

Daniel knows that for the next ten years he will have to compete against Mexico, which, unlike Quebec, has no shortage of labour.

Well aware of this situation, competitors are investing more in Mexico than they are in Canada.

This is why a new factory 4.0 will be up and running in Granby by 2025. The aim is to run a factory with the same workforce.

If the same person can produce twice as many tanks, I have 50% less labour per product, so I’m more competitive!

This involves improving processes, robotization, artificial intelligence and a $30 million investment. Tremcar aims to triple production in Saint-Césaire with the same workforce by manufacturing 1,000 tanks instead of 350.

The challenge is staffing – and at Tremcar, we love challenges!

Tremcar – English

790, avenue Montrichard

Saint-Jean-sur-Richelieu (Québec) J2X 5G4

Publisher: Memorial Edition

Publishing Director: Audrey Dallaire

Author: Roxanne Caron

Translator: Frédérick Poulin

Graphic design: Liliane Racine

Graphic designer: Marie-Hélène Taillon

Proofreading: Céline Chabot

Read also

in the same sector

of activity

Fabrication

PH Tech – English

Construction, Fabrication

Chaudière-Appalaches

Groupe Cambli – English

Fabrication

Montérégie

AGT Robotique – English

Fabrication

Mauricie

Paber Aluminium – English

Fabrication

Chaudière-Appalaches

Jambette – English

Fabrication

Chaudière-Appalaches

EcoloPharm – English

Fabrication

Montérégie

Archex – English

Fabrication, Kiosques d'expositions

Montréal

Entreprise Courtval

Fabrication

Estrie

Industries Mailhot

Fabrication

Lanaudière

Conceptromec

Fabrication

Estrie

Groupe Cambli

Fabrication

Montérégie

PH Tech

Construction, Fabrication

Chaudière-Appalaches

Archex

Fabrication, Kiosques d'expositions

Montréal

MÉTATUBE

Fabrication

Saguenay-Lac-Saint-Jean

Metalium

Fabrication

Montérégie

Tremcar

Fabrication

Montérégie

Précision SF Tech

Fabrication

Lanaudière

EcoloPharm

Fabrication

Montérégie

AGT Robotique

Fabrication

Mauricie

Les Industries Rainville

Fabrication

Montérégie

LABPLAS

Fabrication

Montérégie

Shalwin

Fabrication

Mauricie

Produits Métalliques Bussières

Fabrication

Chaudière-Appalaches

RG Solution

Construction, Fabrication

Estrie

Beaucinox

Fabrication

Chaudière-Appalaches

Metalilux

Fabrication

Laurentides

MegLab

Fabrication

Abitibi-Témiscamingue

Tiges 4 saisons

Fabrication

Centre-du-Québec

Paber Aluminium

Fabrication

Chaudière-Appalaches

MMS laser

Fabrication

Centre-du-Québec

Recyc PHP

Économie sociale, Fabrication

Centre-du-Québec

Les Branchés Lunetterie

Commerce de gros et détail, Fabrication, Services

Laurentides

Jambette

Fabrication

Chaudière-Appalaches

Distillerie 3 lacs

Fabrication

Montérégie

V Création

Fabrication

Laurentides

Ferreol

Fabrication

Capitale-Nationale

Les Industries Phomère

Fabrication

Capitale-Nationale

Read also

in the same

region

Montérégie

Groupe Cambli – English

Fabrication

Montérégie

C.A.T. – English

Transport & Entreposage

Montérégie

Trilogie

Communication, technologie & Technologie de l'information

Montérégie

EcoloPharm – English

Fabrication

Montérégie

CEL aerospace – English

Services

Montérégie

Innergex – English

Matières premières

Montérégie

gbi

Ingénierie

Capitale-Nationale, Lanaudière, Laurentides, Montérégie, Montréal

Elecso

Construction

Montérégie

Construction & Expertise PG

Construction

Montérégie

Groupe Cambli

Fabrication

Montérégie

Infrastructel

Ingénierie

Montérégie

C.A.T.

Transport & Entreposage

Montérégie

Innergex

Matières premières

Montérégie

Camions Dubois

Commerce de gros et détail

Montérégie

GROUPE CANVA

Services

Montérégie, Montréal

CEL aerospace

Services

Montérégie

Metalium

Fabrication

Montérégie

Tremcar

Fabrication

Montérégie

EcoloPharm

Fabrication

Montérégie

Viridis Environnement

Économie sociale, Matières premières

Montérégie

Nationex

Transport & Entreposage

Montérégie

Les Industries Rainville

Fabrication

Montérégie

LABPLAS

Fabrication

Montérégie

Distillerie 3 lacs

Fabrication

Montérégie

Équipement St-Germain

Construction, Transport & Entreposage

Capitale-Nationale, Montérégie