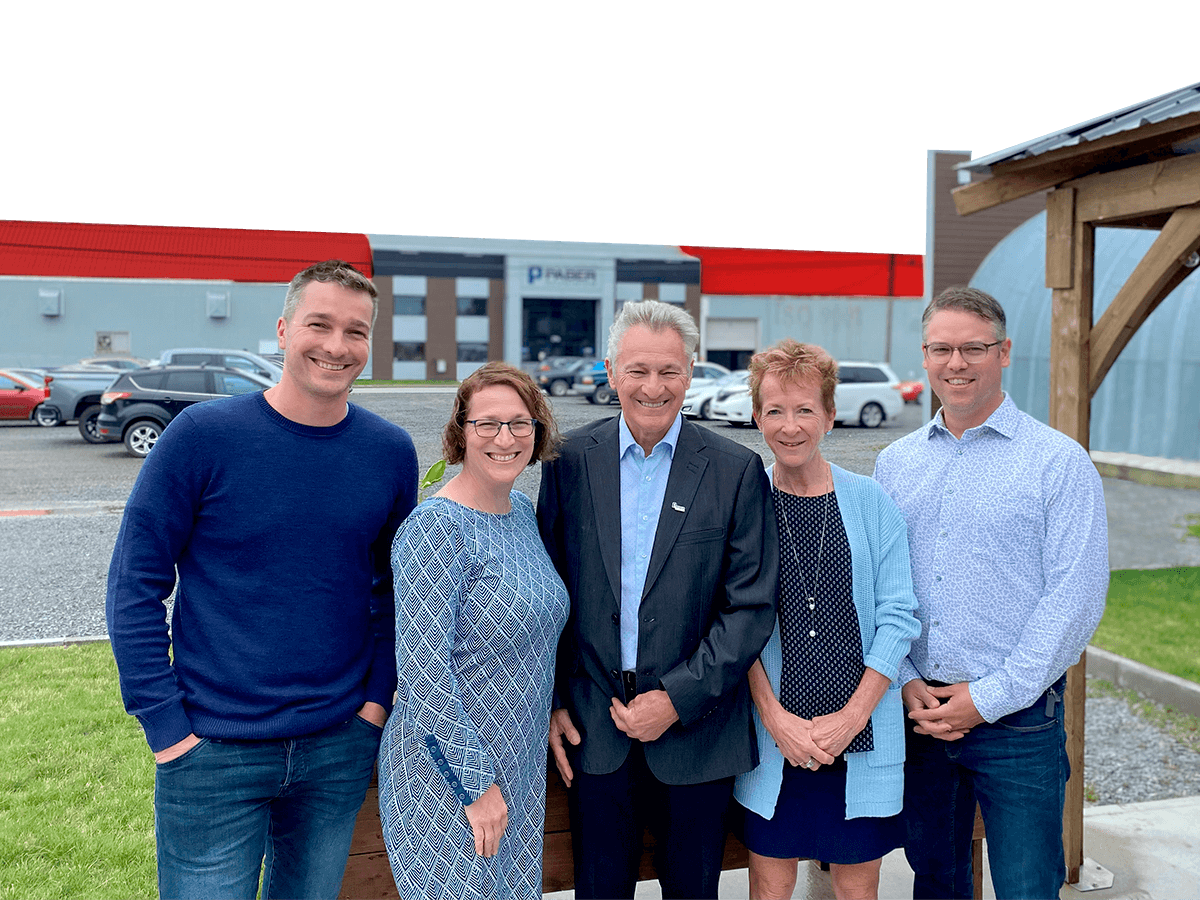

Paber Aluminium Bryan Paris Geneviève Paris François Couillard

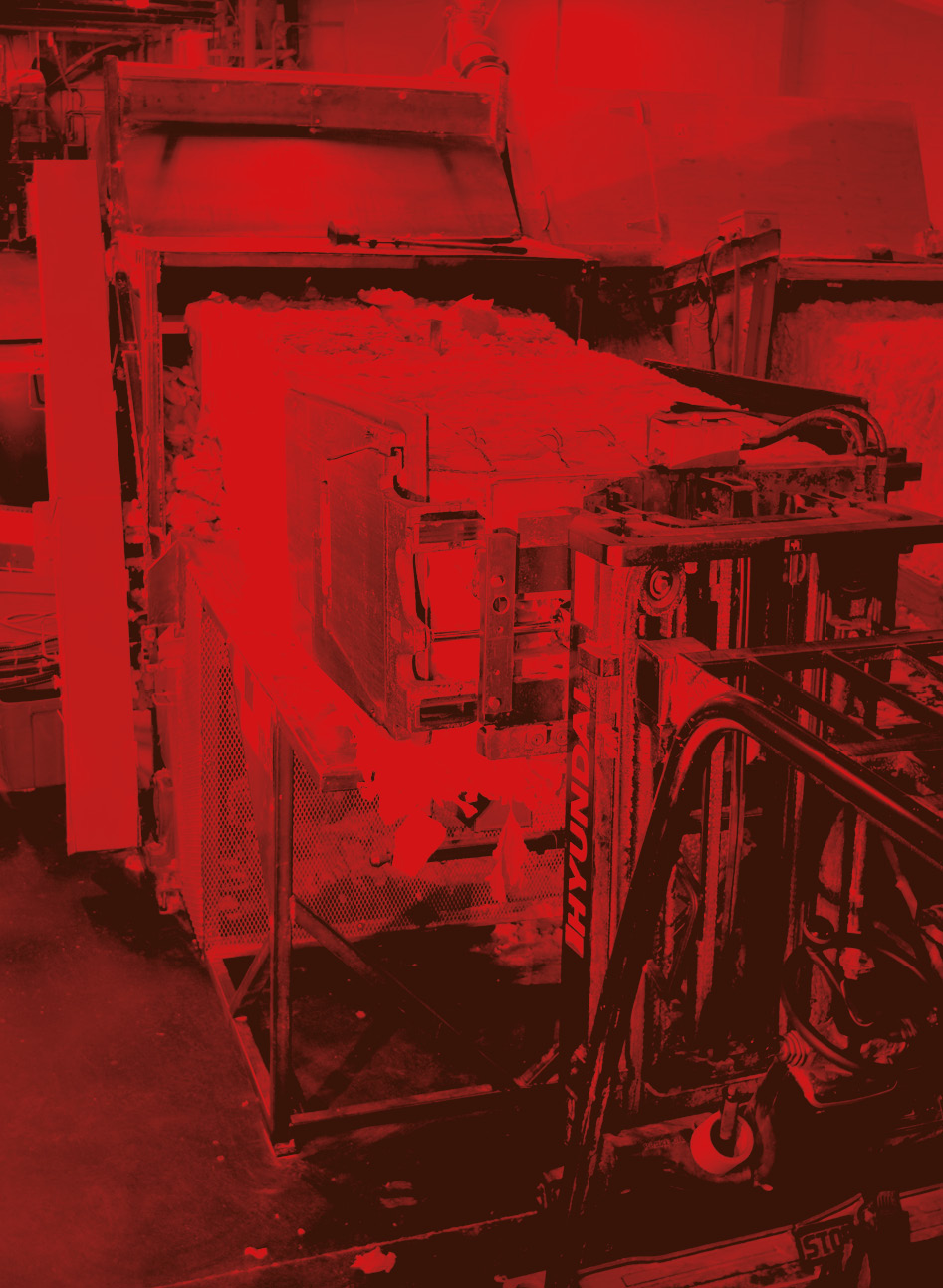

Fabrication

Chaudière-Appalaches

Specialized in high quality gravity aluminum casting, Paber is a Canadian aluminum components manufacturer. Paber produces turnkey parts for clients of various backgrounds around the world. With founder Luc Paris’ two children at the helm, Paber excels where many fail in the transfer of entrepreneurship.

Share on social medias

Share on social medias

The genesis...

Diving head first

At the time, Luc Paris worked in a cast iron foundry. However, several clients told him that there was a lack of aluminum foundries in Quebec.

That’s all it took for Luc to embark on an adventure which, unknowingly, would change the course of his life. In 1981, he founds Paber Aluminium with his friend Mario Bernier – a contraction of Luc’s and Mario’s last names. As they are the only two employees at the time, they set up shop in modest offices.

Despite the need, the growth is not very fast. A first client allows them to get their feet wet in the field of industrial sewing machines. But this contract is not enough to keep Mario. He leaves the project three years later to work in the field of supervision and machining. Meanwhile, Luc’s wife joins him to take care of the accounting. She stays by his side throughout the development of

the company.

Only two years later, that we were five-six employees.

Luc is swimming in the unknown: he is making bold choices without really knowing in which direction they will take him. “It wasn’t a field I knew much about – foundry per se. I studied architectural design.”

He then learns how to cast parts “on the job” and he takes on the challenges whenever they come his way.

Luc Paris in 1981

Adventure

In 1986, a first major contract with a lighting and urban furniture company allows Luc and Diane to spread the wings of their young company. This project is even honoured at a ceremony organized by the Cap-Saint-Ignace Chamber of Commerce.

The couple takes a major step forward in 1991 by moving to a considerably larger building.

When we moved, we had all the equipment placed and were still able to drive a truck around. Now, we’re having a hard time moving around in a forklift!

Audacity

Luc Paris

Founder

A certification worth its weight in gold

With an order book slowly growing and a building to match their ambitions, Diane and Luc set up a complete quality management system which guarantees that their products meet the highest standards.

In 1994, they successfully receive the ISO 9001 certification.

In order to take their business to the next level, they add a production process, install a heat treatment and acquire an X-ray chamber, which at the time is the largest in North America. All of this in only six years.

It really opened the door to exportation.

In the mid-2000s, the medical sector represents a large part of the order book.

Two major American clients in the medical field have really allowed us to grow, increase our sales and build recognition in the United States.

Confidence of steel

The word “problem” is not in Luc’s vocabulary. In 2006, when the X-ray was installed, no employee knew how to use this new technology. This didn’t prevent him from moving forward to stand out in the marketplace. He took advantage of the expertise of an outside firm before training his employees onsite. They moved on to become seasoned machine operators.

The same philosophy applies when he has to set up a machine shop during the same year, a mandatory step to make Paber grow.

It wasn’t always fun, but we still ended up succeeding with a nice, high-performance machine shop.

Vision and values...

A defining dinner

At a business transfer conference, Luc and Diane learn the importance of giving their children the opportunity to take over the company.

During a family dinner, they ask Geneviève and Bryan whether they are interested in taking over the business. The answer is yes! Then begins a 13-year transfer process which officially concludes in 2015.

Geneviève

After university, Geneviève is involved in several departments: quality, project management, hiring and production. She has held the position of general manager for 10 years and is an integral part of Paber’s evolution. She now focuses on logistics, strategy and communication.

Bryan

Bryan has been involved with the company on and off since he was 14 years old and has worked in every position in the plant. He joins the company full time in 2007.

I was interested in growing within the company, but I hadn’t determined which position I was aiming for.

He spends several years in sales before succeeding his father as president.

A credible success

When Luc and Diane announce that their children will go on with the business, they are congratulated by many. They feel fortunate to have completed a process that went well overall. Especially since it adds credibility with external partners.

We heard stories about other people who was in a family succession that was more like a nightmare. We consider ourselves fortunate in the process we went through.

Major advantage

How to successfully transfer a business?

For the complete handover of the presidency, the family goes through different stages.

A family council headed by a human resources coach is created to ensure a progressive transfer.

“Our coach would organize meetings based on evolution and progress. We each had little assignments. We had to adapt.”

Their journey is also greatly influenced by the Groupement des chefs d’entreprise, which the Paris family belongs to. “It is still a very present organization.”

Another great asset established 30 years ago is the advisory committee, the committee is made up of the shareholders and two to three outside members who are willing

to provide advice. The latter come and go depending on Paber’s current needs and evolution. One of the members has actually been on the committee since its inception!

It’s a priceless opportunity to have him at every meeting even though he’s retired.

This committee is particularly important to the family as they must come well prepared for these meetings. “We have no choice but to meet the deadlines we set for ourselves. It puts a little pressure on us!”

Knowing how to surround yourself

François Couillard joins Paber as the company is being transferred. The family feels it is time to have onsite someone to take care of the administration and accounting. “They really created a new position for me here.”

Already a friend of both Geneviève and Bryan, François becomes vice-president of finance and has the desire to become an entrepreneur. “They felt comfortable with me joining the succession.”

At the École d’entrepreneurship de Beauce, François participates in a bootcamp while Bryan, Geneviève and their parents are involved in various programs leading to the transfer of the business. This school is very significant for the family as it represents a pivotal step in the progression of the transfer process.

Bryan and I are brother and sister, it’s not always easy! Sometimes, it is a bit challenging. Among other things, the École d’entrepreneurship de Beauce helped us get through some of those challenges.

Succession

MERCURIADE Award for Entrepreneuriat, relève et transfert d’entreprise Raymond Chabot

Grant Thornton from the Fédération des chambres de commerce du Québec – 2017

Photo credit: Chambre de commerce et d’industrie de la MRC de Montmagny – CCIM

Rules

Putting aside the rhetoric

There is no perfect recipe for a successful transfer of business. If the Paris family’s transfer runs smoothly, it’s because they set some very strict rules from the start: no talking about work at family dinners.

We take this very seriously.

This arrangement prevents work-related family disputes. By joining the company, François knows things can get a little risky.

Part of the success of the transfer is establishing and maintaining strict rules throughout the process.

Local flagship

From the very beginning, Luc’s motivation is to make the company evolve, first and foremost to create and maintain jobs in Cap-Saint-Ignace, a small village of less than 4000 inhabitants.

These are people, these are families that we put to work and who rely on us.

On top of that, he wants Paber to be transferred to his children precisely to ensure that jobs remain in the region and that human values are preserved.

“We could have sold it to Americans on occasions but today, Paber would have then gone somewhere else and probably wouldn’t carry that name anymore.”

Gala Les Mérites STIQ, 2017

(Sous-traitance industrielle du Québec)

An ironclad belief

Tools

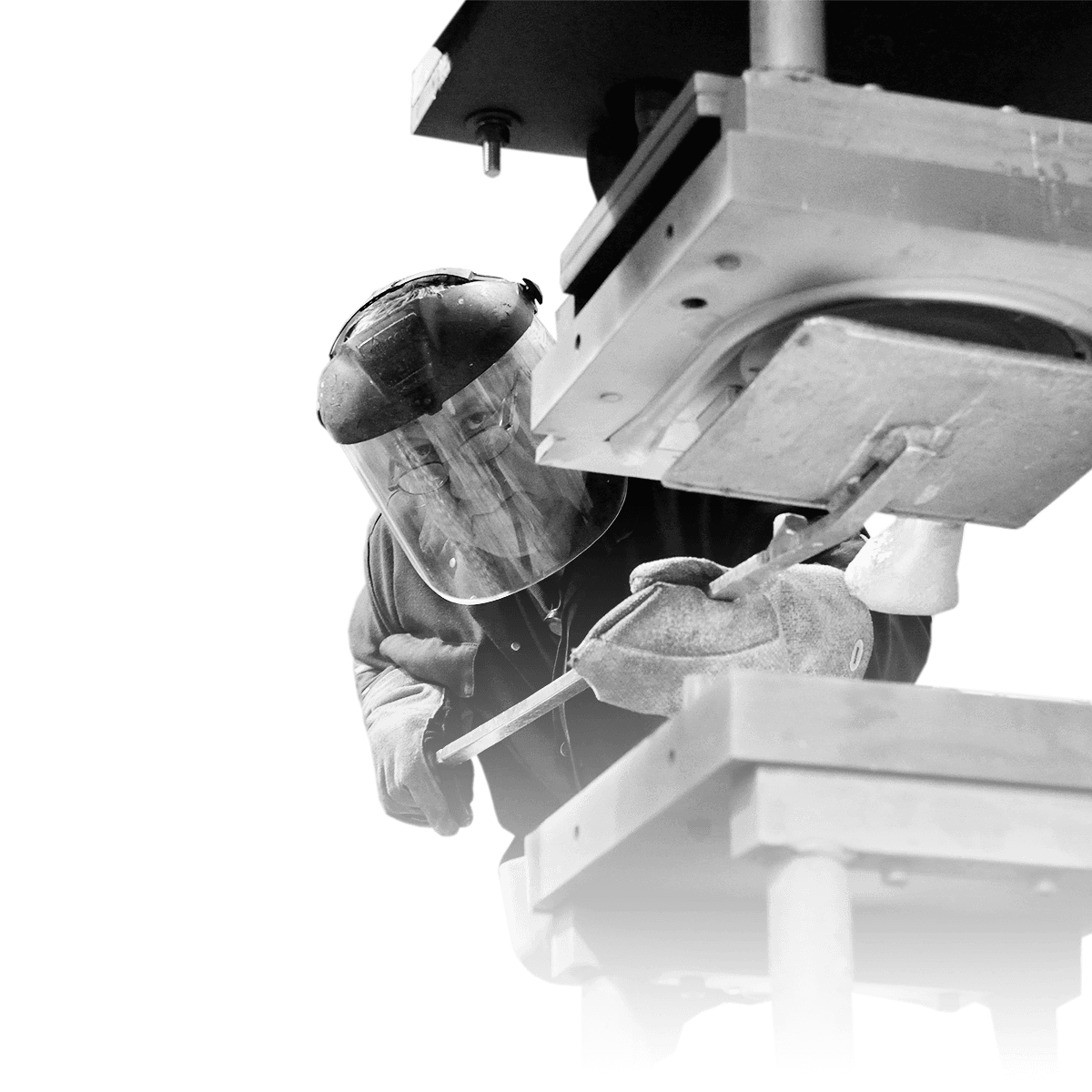

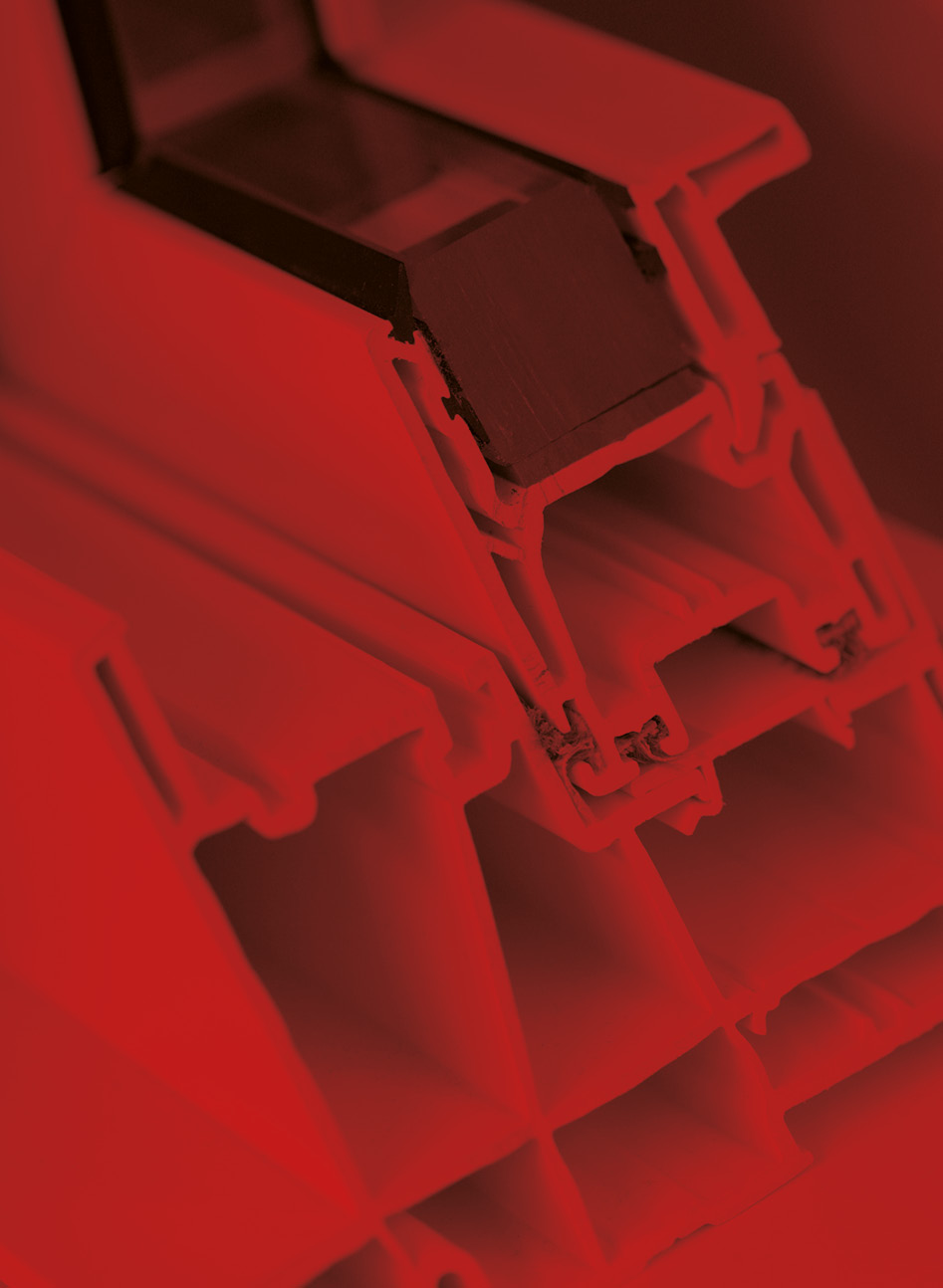

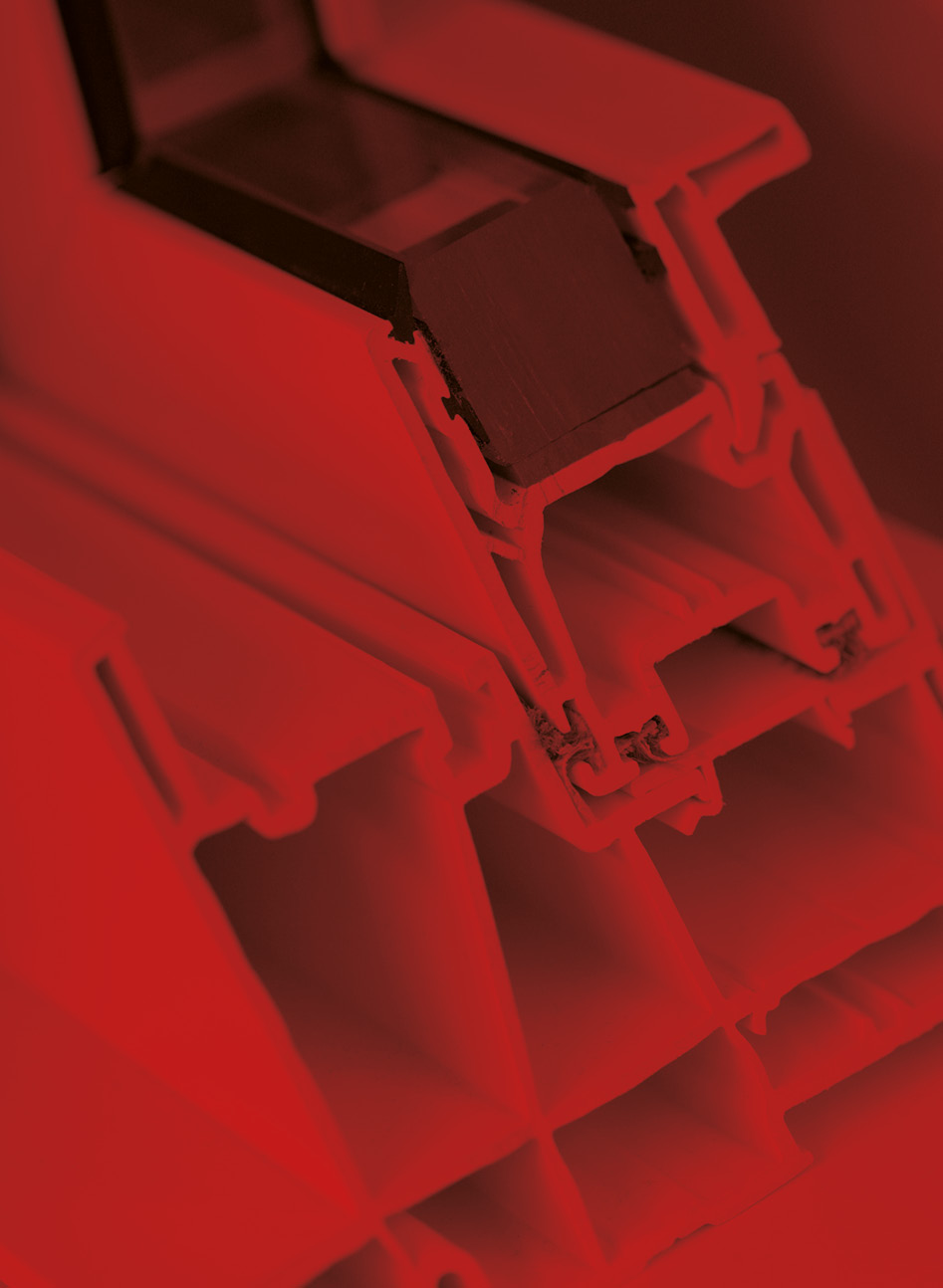

While Paber already masters sand casting, a new process is integrated into the plant in the late 1990s: permanent molding. This new division brings along its own difficulties.

It wasn’t necessarily a new process in the industry, but it was new to us.

Every year, they put a lot of energy into it, hoping to cross the learning curve, which finally takes more than 10 years to achieve.

“It was a volume issue back then. We didn’t have enough business to make it profitable.” Every year until 2015, the family wonders about the financial results of permanent molding. “We were asking ourselves: do we stop or do we continue?”

Bryan, however, is attached to this new expertise and sees in it the potential for Paber to stand out, although he is aware that he may sometimes overdo it a little…

It was a competitive advantage we had. Did I think it was efficient? No, but I still wanted to keep it. And now, we’re putting the effort in to make it something more profitable and advantageous for us.

At the crossroads in 2022, Paber has the required volume for the department to expand and is deploying the necessary resources to improve its technical expertise.

Following your instinct

In fact, the entrepreneurs behind

Paber tend to rely more on their instinct than on numbers, because they are attached to their projects.It’s not just rational. There’s hope, there’s determination, there’s emotion mixed in with all of that.The family also relies on François to balance emotions and rationality.

In the mid-2000s, Paber welcomes a new client who manufactures various medical equipment. Once again, meeting the requirements of this contract is a long learning curve.

Bryan, who thrives on challenges, is fully committed to the project because he sees the potential of this contract and the exposure it could bring them. He puts everything in place to make it work.

“It’s now our biggest client!”

François, however, is never too far behind to put numbers on the table and establish timelines.

I’m there to cut the fun a little bit!

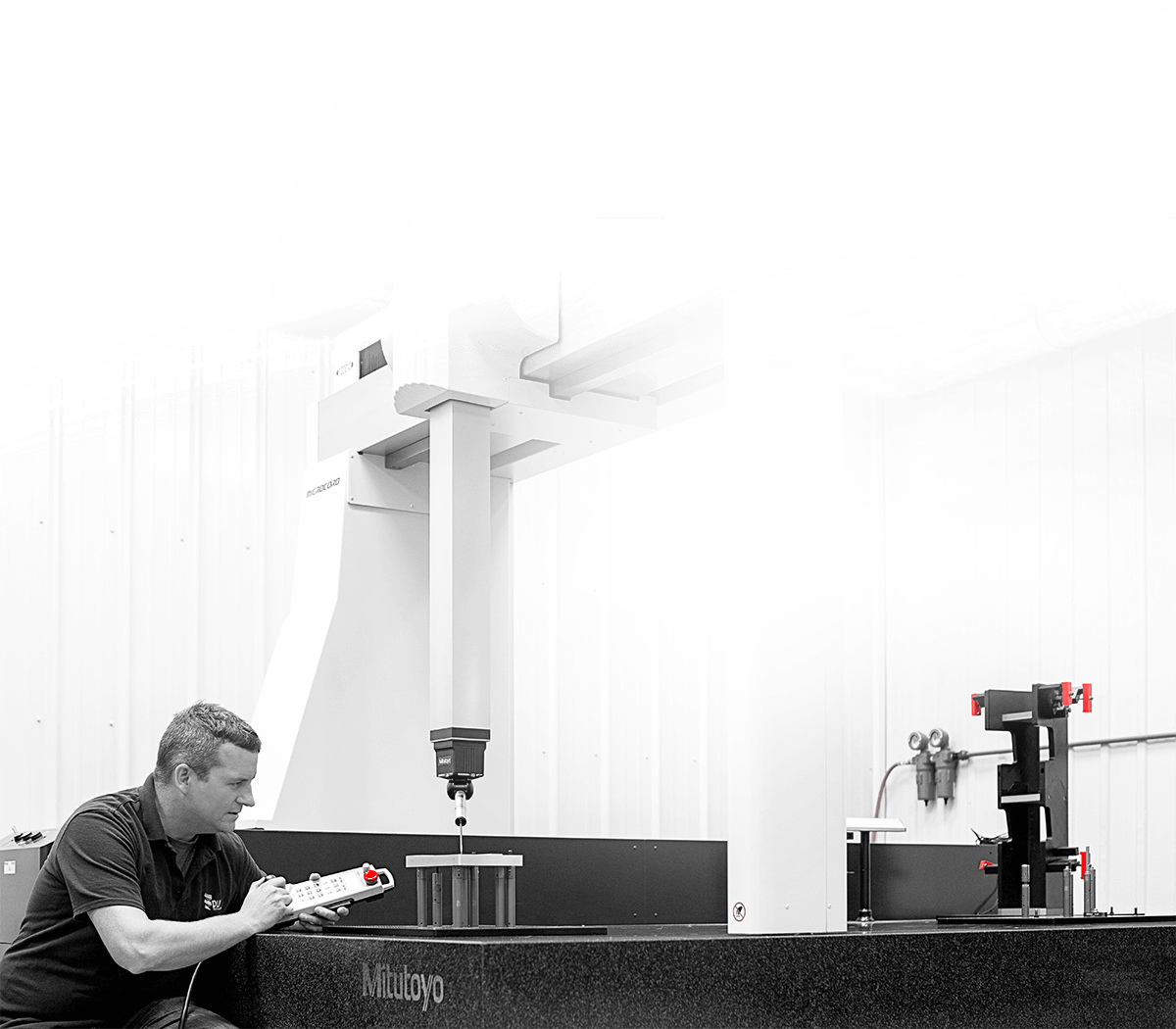

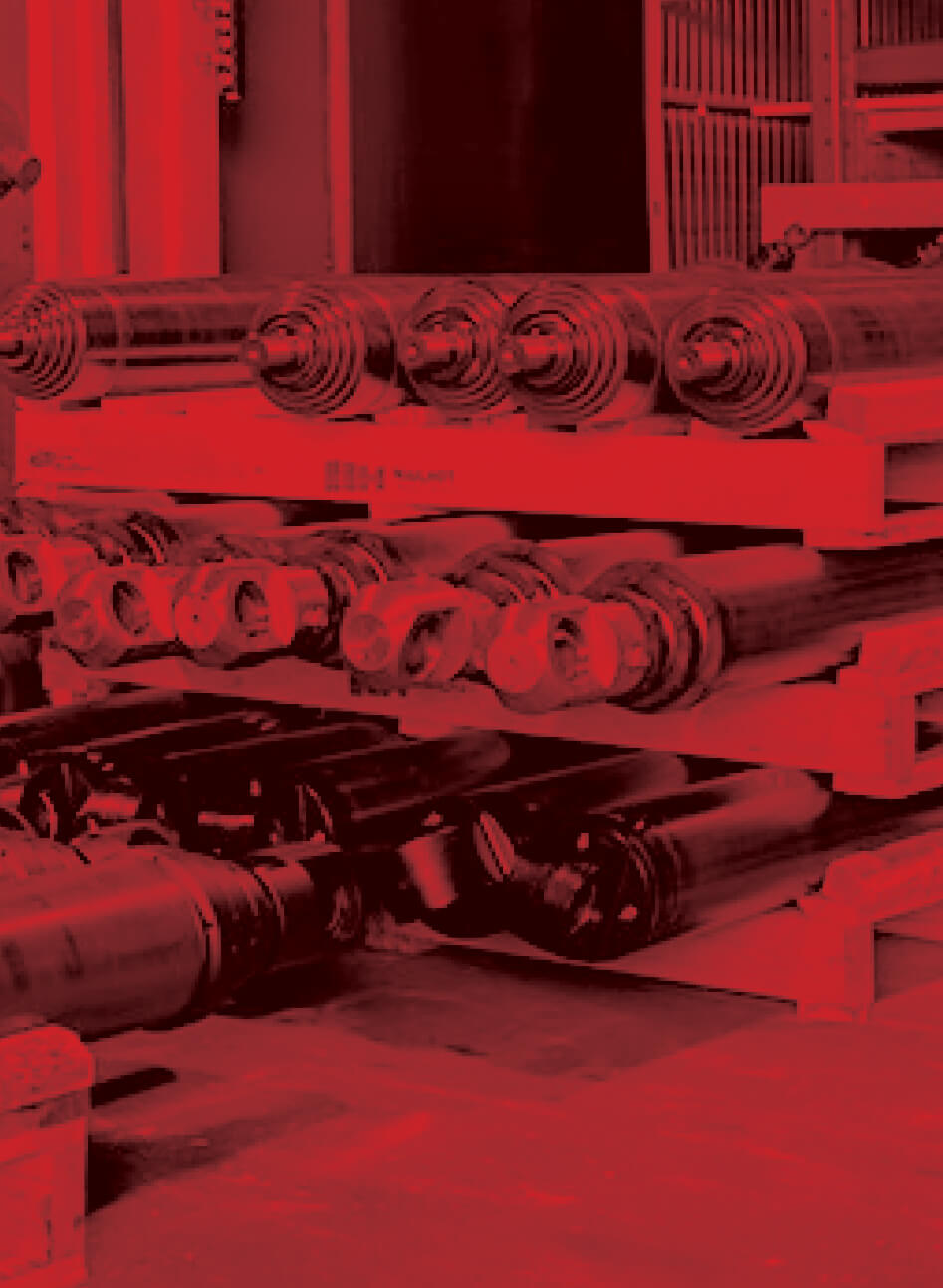

Perfect control

With several production processes, Paber integrates all operations from A to Z in-house. The aluminum part is produced, along with the value-added heat treatment, machining, quality testing, etc. For them, it is a good thing to remove subcontractors from the equation.

It was causing us a lot of management, problems and costs.

Since the 2010s, Paber has great momentum with the addition of new clients. In 2018-2019, it stabilizes its sales and development while making several investments in equipment, combining different technologies. Paber also integrates a first and a second robot in its machining division. Two more are added in 2022.

Automation allows for a certain stability, capability and consistency in our processes.

Plans

Behind the scenes...

The ambitious dreamer

Bryan Paris

President

After high school, Bryan spends a year in Vancouver to learn English. He then goes to Hamilton, Ontario, to study industrial engineering before coming back to Quebec to complete a year in industrial relations. While working part-time at Paber, he earns a bachelor’s degree in administration. A dreamer, he thrives on challenges.

“I love to see projects and imagine them in the future, even though they’re not always straightforward projects.”

Bryan, who is afraid of nothing, takes great pleasure in going for had to get clients.

The organized planner

Geneviève Paris

Vice-President

Geneviève holds a bachelor’s degree in business administration from Université Laval in Quebec City. At Paber, she began her career in customer service and then moved into production planning where she held a number of positions. Geneviève then started a Diploma of Vocational Studies (DVS) in foundry in order to learn the inner workings of the various trades in the plant.

“It allowed me to get a technical expertise in foundry I didn’t have in order to support my administrative skills.”

Geneviève is a structured, well organized person. She knows how to apply the rules and build an organizational structure.

“I don’t have as much vision for the market as Bryan. I trust him completely on that. For my part, I look at how we’re going to proceed in order to make it work.”

Challenges

François Couillard

Vice-President of finance

A chartered accountant, François brings a more rational side to the team. This does not prevent him, just like Bryan, from having an unquenchable thirst for challenges. Reflective, he analyzes the investments needed to bring added value to the company. He likes to surround himself with a team that allows him to move forward.

“I’m a team entrepreneur. I’m not the accountant who locks himself in his office!”

Projects

An overview of the future...

Stabilize to optimize

With two plants, one of 88,000 square feet and another of 17,000 square feet, Paber is becoming cramped in its facilities.

Geneviève, Bryan and François are therefore developing a very embryonic project of building a new, more suitable plant on a piece of land in Cap-Saint-Ignace that they already own.

On a short-term basis, Paber wants to optimize its facilities, equipment and work shifts while automating the processes as much as possible.

The goal is to create jobs requiring less physical efforts to have better comfort at work.

With the pandemic having reduced some of the business volume, the company is repositioning itself for the next steps in order to grow again. First, they want to stabilize production to serve current clients well and continue to develop relationships with new ones to ensure diversity in their domain.

“There’s a market both in Quebec and internationally for aluminum, it’s really a market for the future, so there’s a huge potential for us.”

Paber Aluminium – English

296, chemin Vincelotte

Cap-Saint-Ignace (Québec) G0R 1H0

Publishing Director: Audrey Dallaire

Author: Roxanne Caron

Translator: Frédérick Poulin

Graphic designer: Liliane Racine

Graphic artist: Marie-Hélène Taillon

Proofreader: Céline Chabot

Read also

in the same sector

of activity

Fabrication

À venir

Qualtech

Fabrication

Capitale-Nationale

PH Tech – English

Construction, Fabrication

Chaudière-Appalaches

Groupe Cambli – English

Fabrication

Montérégie

AGT Robotics – English

Fabrication

Mauricie

Tremcar – English

Fabrication

Montérégie

Jambette – English

Fabrication

Chaudière-Appalaches

EcoloPharm – English

Fabrication

Montérégie

Archex (EN)

Fabrication, Kiosques d'expositions

Montréal

Entreprise Courtval

Fabrication

Estrie

Industries Mailhot

Fabrication

Lanaudière

Conceptromec

Fabrication

Estrie

Groupe Cambli

Fabrication

Montérégie

PH Tech

Construction, Fabrication

Chaudière-Appalaches

Archex

Fabrication, Kiosques d'expositions

Montréal

MÉTATUBE

Fabrication

Saguenay-Lac-Saint-Jean

Metalium

Fabrication

Montérégie

Tremcar

Fabrication

Montérégie

Précision SF Tech

Fabrication

Lanaudière

EcoloPharm

Fabrication

Montérégie

AGT Robotique

Fabrication

Mauricie

Les Industries Rainville

Fabrication

Montérégie

LABPLAS

Fabrication

Montérégie

Shalwin

Fabrication

Mauricie

Produits Métalliques Bussières

Fabrication

Chaudière-Appalaches

RG Solution

Construction, Fabrication

Estrie

Beaucinox

Fabrication

Chaudière-Appalaches

Metalilux

Fabrication

Laurentides

MegLab

Fabrication

Abitibi-Témiscamingue

Tiges 4 saisons

Fabrication

Centre-du-Québec

Paber Aluminium

Fabrication

Chaudière-Appalaches

MMS laser

Fabrication

Centre-du-Québec

Recyc PHP

Économie sociale, Fabrication

Centre-du-Québec

Les Branchés Lunetterie

Commerce de gros et détail, Fabrication, Services

Laurentides

Jambette

Fabrication

Chaudière-Appalaches

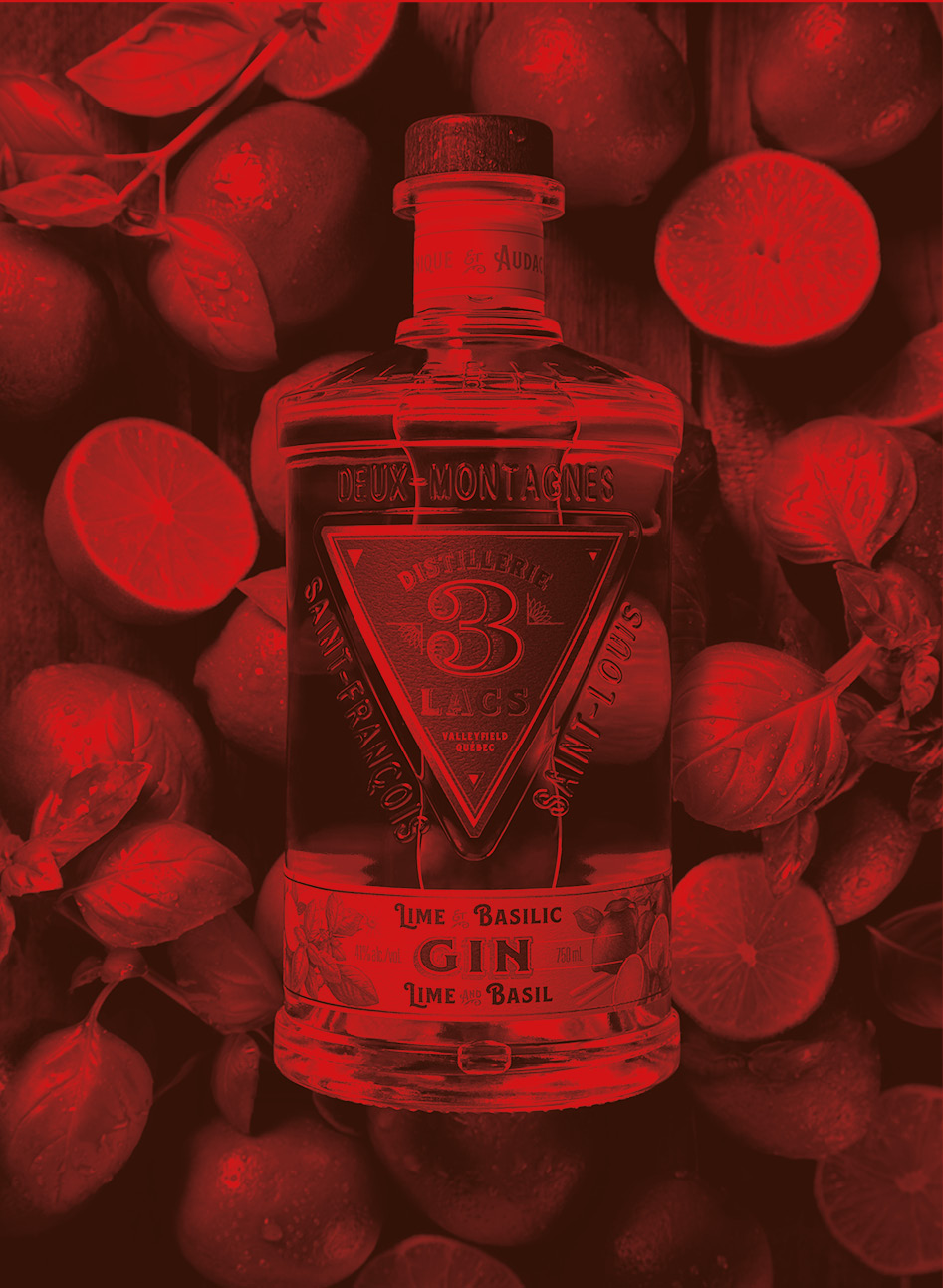

Distillerie 3 lacs

Fabrication

Montérégie

V Création

Fabrication

Laurentides

Ferreol

Fabrication

Capitale-Nationale

Les Industries Phomère

Fabrication

Capitale-Nationale

Read also

in the same

region

Chaudière-Appalaches

FC géosynthétiques

Construction

Chaudière-Appalaches

PH Tech – English

Construction, Fabrication

Chaudière-Appalaches

Everest Automation – English

Services

Chaudière-Appalaches

Jambette – English

Fabrication

Chaudière-Appalaches

Everest Automation

Services

Chaudière-Appalaches

PH Tech

Construction, Fabrication

Chaudière-Appalaches

Firebarns

Alimentation

Chaudière-Appalaches

J.M. Demers

Construction

Chaudière-Appalaches

Produits Métalliques Bussières

Fabrication

Chaudière-Appalaches

Beaucinox

Fabrication

Chaudière-Appalaches

Paber Aluminium

Fabrication

Chaudière-Appalaches

BEAUCE SPORTS

Commerce de gros et détail

Chaudière-Appalaches

Jambette

Fabrication

Chaudière-Appalaches

Mobile-Punch

Communication, technologie & Technologie de l'information

Chaudière-Appalaches

Enviro Confort

Construction

Chaudière-Appalaches

Gabion Express

Construction

Chaudière-Appalaches