Richard Boucher Guy Caron Claude Caron Marie-Noël Grenier Jordan Boucher

Fabrication

Chaudière-Appalaches

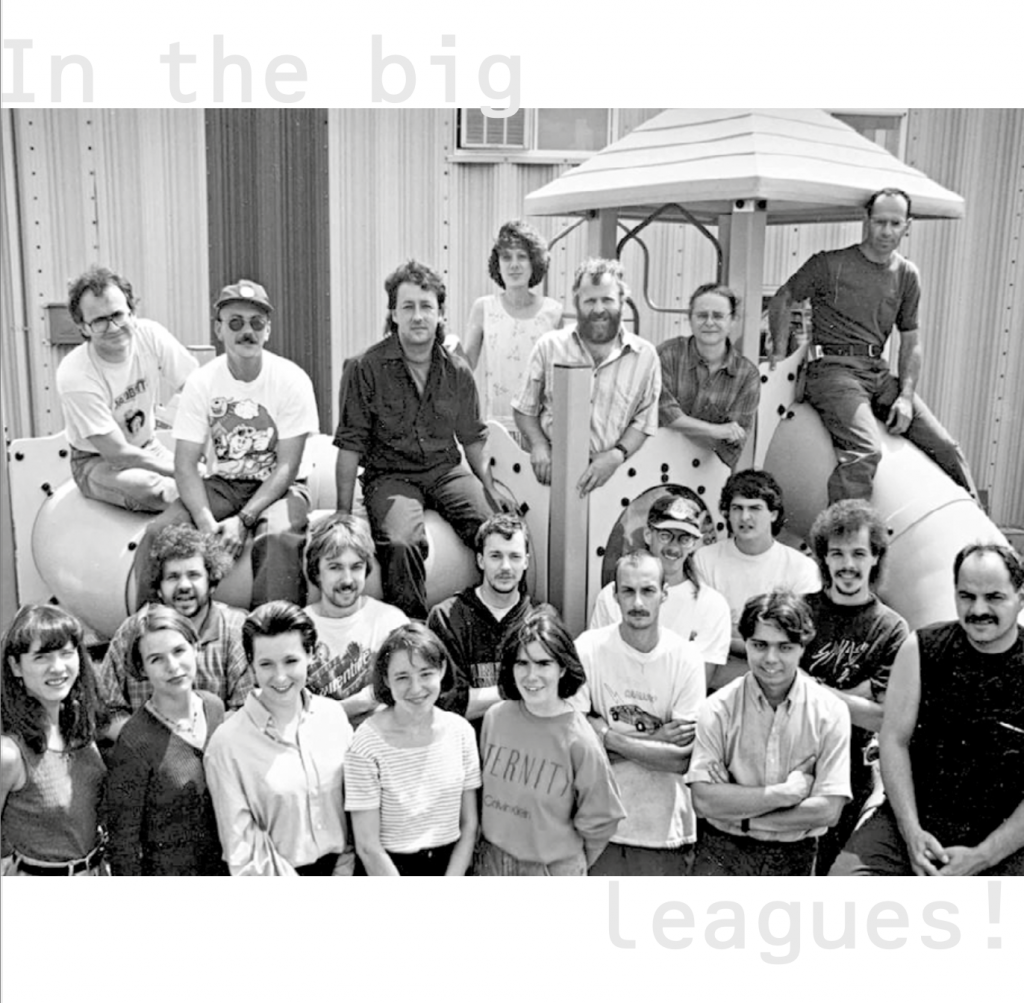

The Jambette recreational equipment company was a small business when it was founded in Lévis in 1983. Its values of openness, sharing and generosity have helped it grow so well that this Canadian leader in playground equipment design is now playing in the big leagues.

Share on social medias

Share on social medias

The genesis...

When work becomes a game

Starting out as a small manufacturer of playground equipment and park furniture, Jambette is now a Canadian leader which climbed the ladder one day, one game, one park at a time.

Richard Boucher and Claude Caron are finishing their DCS in architectural technology at Cégep Lévis-Lauzon when one of their teachers offers them a contract to design a swing set for the company Le Nord. The two students invest three weeks in this mandate during the summer of 1977.

Claude is then hired at Davie shipyard and Richard continues to design swings for Le Nord until its closure some time later. During his employment, he learns to design, draw, build and install play modules.

Over a meal, Richard suggests to Claude to resume the game manufacturing.. The idea makes its way and on June 28, 1983, Richard and Claude register Équipements RC enr. They complete a first mock-up of a play set that would be used to promote their company and its products. Claude and his spouse, Claudette Poiré, bring it to the parc de la Paix, in Lévis, to photograph it so that it looks like an actual play set in a sandbox.

The photograph was taken from above, as if we had a drone. We were already precursors !

innovative

Born developers

During the start-up, Claude’s brother, Guy Caron, studies recreology at the Université de Trois-Rivières and wants to join the company to handle marketing and sales. Claude and Richard therefore agree to include him in the team.

The two Caron brothers are recognized for their entrepreneurial skills, as demonstrated in their childhood, having managed a small ski resort in Lévis as volunteers and having contributed to the development of bicycle tourism.

We are sort of the pioneers of what is now Vélo Québec.

A hard worker, Richard does not see himself as much as an entrepreneur, but he never hesitates to double his efforts to contribute to the growth of the company.

Jambette

Claudette Poiré then goes through an architectural dictionary when comes the time to find a catchier company name. She then finds the word “jambette”, which is a small support piece in the roof structure of ancestral Canadian houses. The word well represents the company which manufactures wooden play sets, while being a wink to the “jambette” that children give each other when playing (the word also means to trip someone).

From a marketing perspective, we thought it was interesting! We ended up going with that name.

Committed spouses

Each in their own way, three men’s wives participate in the creation of the company.

Thanks to her artistic talents, Claudette is an early pioneer and dabbles in all areas, mostly on a volunteer basis, for fabrication, installation, welding, design, etc.

At the time, Richard’s wife, Lucie Paquet, works as an administrative assistant for the city of Quebec. With her contacts, she obtains free furniture, sells her car to the company, convinces her father to invest in the purchase of shares, etc.

generosity

Lucie and Jordan

Until they get an office, Jambette’s phone line was connected to Guy’s apartment. He and his wife, Danyèle Gagné, look eagerly for any phone messages left on the answering machine.

As we just mailed our flyers, we were hoping for replies. The first message left on the answering message was from the municipality of Valleyfield, which wanted information.

Danyèle and Guy

Claudette

Handymen at work .

Jambette finally lands its first contract with the municipality of Contrecoeur, in the Montérégie region.

Richard and Guy drive to Contrecoeur to meet the officials in an old car that is not really reliable. “That was quite an adventure!”

Every time a deal is sealed, the three men gather in the workshop to build the play set immediately.

All three of us are handymen.

Richard explains to Guy how to do it and Guy gets to work. Claude, who works at the Davie shipyard, lends a hand with Claudette on evenings and weekends.

Once a play set is done, we try to sell another one.

Claude’s permanent employment allows the trio to have their first line of credit, although financing is difficult to obtain. Claude is keen on putting together financial documents and goes to his uncle to learn the basics of accounting.

A very first plant!

In 1986, Jambette builds its first plant in the Lauzon industrial park. The government in place is providing subsidies to entrepreneurs who have construction projects. The team succeeds in meeting the financial requirements and receives the anticipated subsidy.

“I was quite proud to have a check in my hands from the provincial government, signed by Pauline Marois!”

However, the financing was conditional on the company finding a lender for an equivalent amount and making a down payment.

“Around 1985, those were our first steps as businessmen.”

After several refusals, a director for the Business Development Bank of Canada, Diane Déry, agrees to finance them.

A market to conquer!

In North America, the market for manufactured games intended for public parks evolves after the World War II.

It was not uncommon to see companies manufacturing farm equipment also produce steel or metal playground games, which they sold in Quebec through distributors. The province of Quebec had only one manufacturer of Quebec products.

Our main competitors were the parents who would buy wood at the hardware store and build games for their children on weekends at school. There was a lot of volunteering involved in making the games back then, which does not exist today because there are regulations.

Contracts

Taking the regions by storm!

In its early days, Jambette mainly serves the different regions of Quebec, such as Mauricie, the Eastern Townships, the Côte-Nord and the Gaspé Peninsula. “We made gains because the others weren’t going there.” Competitors instead focused their activities in “the jungle” of large centres. The young entrepreneurs therefore had a free hand.

We seized this opportunity.

The contacts that Guy made during his university studies in recreology are a great help to the sales department. Several of his former classmates now work for municipalities, national parks, schools, etc.

“They then become potential clients for Jambette.”

The company uses the directory of Quebec municipalities, educational institutions and daycare services and sends each one its small catalogues and brochures by mail.

The fact that Jambette offers Quebec products is important for clients, who are open to the idea.

Of course, we had to prove ourselves!

For the smooth running of operations, Jambette is divided into three entities: Richard is in charge of production, Claude of administration and Guy of sales.

Each one was master of his own kingdom. Each one decided in his respective department.

This division of tasks is one of the keys to their success.

Having fun at work, despite the tensions

Of course, the three partners have differences of opinions and arguments from time to time. “Since the three of us know each other intimately, sometimes we would not shy away from going a little far, but the friendliness would always come back. Nothing serious ever happened.”

Claude sometimes uses his skills as a mediator between his brother Guy and his childhood friend Richard. For the three men, it is important to maintain a pleasant climate with everyone. The pleasure of working is part of Jambette’s DNAs. Most of the time, tensions are related to delivery times. Playground equipment manufacturing is a seasonal business, with demands peaking during periods such as National Day, before back-to-school and the winter freeze-up, among others.

Guy makes commitments to clients to deliver the play sets on a set schedule, but production fails to deliver the goods on time as promised. “We were delaying deliveries from week to week. It was becoming unbearable for the people who were on the phone.”

Their journey is also greatly influenced by the Groupement des chefs d’entreprise, which the Paris family is part of. “It was then a very present organisation, and still is.”

We couldn’t pull off miracles !

Make or break

The company finds several solutions to remedy the situation and goes into innovation mode in the early 1990s by abandoning wooden play sets and replacing them with new steel and aluminum models.

The fashion for wooden play sets in public parks was part of the American trend that began in the late 1970s as the outdoors industry began to develop by building national parks for hiking.

Jambette followed this trend until it ran out of steam and changed over again.

Selling new steel and aluminum play sets is difficult for Jambette which is facing a tough market. “We sat down with Diane Déry and told ourselves that we had to relaunch our marketing image and that we needed a large catalogue.”

No bank was willing to finance this expense which was too risky. Before granting the loan, the adviser warns the three shareholders: “This is make or break, “kids”. I am lending it to you and it has to work. If it doesn’t work, we’re all in trouble…”

Winners!

Luckily, the relaunch works and Jambette stands out with its “Stop Vandalism” initiative which promotes its fight against this social phenomenon.

“It put us on the map. It really was a good move!”

With this program, the company was trying a new approach: positioning itself ahead of the product, first promoting its philosophy and culture. “Since the product was getting lost in the shuffle, we became known by selling ourselves. It was a very bold approach at the time.”

In 1996, Jambette wins the Mercure award at the prestigious Mercuriades competition, the highest entrepreneurial distinction in Quebec.

At the award ceremony, Mr. Dutil, a businessman from Beauce, told them that the first million was the hardest to make. For the next seven years, Jambette’s sales increases by one million dollars each year.

Vision and values...

The next generation is here

Jambette’s current president, Marie-Noël Grenier, joins the company in 1998 while studying management accounting.

As time goes by, this woman of challenge holds several management positions, being Claude’s “right hand”. When she is offered the position of general manager in 2007 and the opportunity to become a shareholder, she can’t say no! Like all those who have contributed to building the company, she has the word “Jambette” tattooed on her heart. In 2012, she acquires more shares and becomes president.

fresh blood

Marie-Noël Grenier and Claude Caron

Teamwork!

The synergy that motivates employees and shareholders to clearly identify problems and tackle them as a team makes all the difference in this Chaudières-Appalaches company.

It’s not a single person who decides. It’s the group!

Humane

The team’s strength was felt during the first years of Jambette’s existence, when several people close to the founding group invested $5,000 in shares to provide the company with working capital.

Before these valuable supporters were reimbursed in the early 2000s, they were receiving dividends every year. While Claude’s father was hesitant at first, he was disappointed when his son paid him back his investment because he was proud to be a Jambette shareholder. “Moreover, it was his highest paying investment!”

Chambre de commerce de Lévis Pléiades – Prix d’Excellence 2009

Opportunity

Grabbing the ball

Around 2011, the company begins to manufacture its play sets with round posts, which improve the psychomotor block, instead of the old square models. Once again, the entire staff is working hard to make this change. Within 2 years, more than 400 new products are redesigned to fit the round posts.

This valuable staff engagement allows to seize every golden opportunity that presents itself. “We’re pretty good at seeing opportunities and turning around quickly. We always have been! From one season to the next, we’re able to change our catalogue, our type of approach, etc.” When a key person leaves the ship, the team takes the opportunity to make major changes as needed. “We see this opportunity! Had the person stayed, we wouldn’t have been able to do so. As they leave, we figure we can!”

It changed the dynamic! It made a revolution. We had to roll up our sleeves!

Innovative signature

Sacha, Claude and Marc

Design Exchange Award competition.

The hiring of a designer in the mid-1990s propels the company to become a leader in the creation of new models within the Canadian recreational equipment industry.

Designer Marc Boudreau, who joins the team as an employee and then as a subcontractor, creates a multitude of new play sets.

His arrival marks a new era, the emergence of Jambette’s innovative character, which will continue to be renewed thereafter.

Most of Jambette’s products are its signature.

During this period, the company implements the Toyota system in its production, well before many companies and government organisations better known to the general public.

This value-added production (VAP), focused on organisation and planning, and solving the problem of delivery times.

We focused on doing the right things at the right time making the most

of it.

Child safety at heart

In 2000, Jambette obtains the IPEMA safety certification, the most important of its kind in America, and at the same time becomes the first company to obtain it outside the United States. Richard, who held a number of production positions until his retirement in 2016, is fully committed to this process in order to comply with the required regulatory framework.

“There was a lot of thought, a lot of technical details to meet in terms of regulations and safety.”

When Richard retires in 2016, his son, Jordan Boucher, who has been involved in the company since 2002, takes over as production manager. Jambette sets in motion its continuous improvement plan. Employees are called upon to propose solutions to make their workstations even more efficient.

They are the ones who are on the operational side. The decisions should come from them.

Productivity increases and the company’s financial strength makes it possible to significantly reduce the number of workers furloughed during slower periods and stagger production throughout the year.

Giving back is important, which is why the company gives 5% of its profits to its employees and 5% to the community every year.

Building

Jordan

Humans first

The human value placed on anyone who is part of the company is an undeniable asset at Jambette.

Marie-Noël is proud of the new program, available on the website, which presents the company’s inclusive and benevolent values.

What really helped me make this journey at Jambette was my empathetic side, my human side.

The company develops an organisational model so that everyone can be autonomous and happy in their work, responding to the learning and achievement needs of individuals.

We believe that everyone, at any point in their life, should have the opportunity to learn. We want to facilitate the acquisition of knowledge and skills by individuals to achieve their aspirations and enable them to contribute to society.

We want to make sure that, like Martin and Daniel after 35 years of creating games, people still feel good and that their work continues to make the world a better place.

We want everyone to feel their contribution and perceive that they are making a difference.

Team

Behind the curtain...

Down with the hierarchy!

Dedicated humans

Among all of a company’s resources, Jambette’s founding group still believes that the human being doing the work is the only one capable of making a real difference.

The same person can well perform in one company and do so-so in three others. If you have the best humans, who are the best mentored and trained ones, the most dedicated humans, those are the ones who are going to help the company.

A few years ago, we said to ourselves that we wanted to be more of a liberated company, to flatten the hierarchy.

Now, it’s a bubble collabogramm that we have. The structures in place support this fundamental mentality of the founding owners, who are filled with pride in the human and Quebec-based company they built.

An outline of the future...

A factory as a gift

Jambette will be getting a brand new, “one-piece” factory for its 40th anniversary in 2023.

The Lévis facility has undergone several expansions to accommodate business growth, so much so that the installations had to be patched together in “many pieces”. The new building will maximise operations to keep up with the annual growth of about 15%.

With sales of around $17 million, Jambette will continue its export efforts, as it already holds a very large share of sales within Quebec.

The employer wants to continue to make the world grow… to make the child grow through its games, but also its hundred of colleagues, by remaining generous!

Growth comes from opening up markets.

Jambette – English

700, rue des Calfats

Lévis (Québec) G6Y 9E6

418 837-8246

jambette.comPublishing Director: Audrey Dallaire

Author: Caroline Lepage

Translator: Frédérick Poulin

Graphic designer: Liliane Racine

Graphic artist: Marie-Hélène Taillon

Proofreader: Céline Chabot

Read also

in the same sector

of activity

Fabrication

À venir

Qualtech

Fabrication

Capitale-Nationale

PH Tech – English

Construction, Fabrication

Chaudière-Appalaches

Groupe Cambli – English

Fabrication

Montérégie

AGT Robotics – English

Fabrication

Mauricie

Tremcar – English

Fabrication

Montérégie

Paber Aluminium – English

Fabrication

Chaudière-Appalaches

EcoloPharm – English

Fabrication

Montérégie

Archex (EN)

Fabrication, Kiosques d'expositions

Montréal

Entreprise Courtval

Fabrication

Estrie

Industries Mailhot

Fabrication

Lanaudière

Conceptromec

Fabrication

Estrie

Groupe Cambli

Fabrication

Montérégie

PH Tech

Construction, Fabrication

Chaudière-Appalaches

Archex

Fabrication, Kiosques d'expositions

Montréal

MÉTATUBE

Fabrication

Saguenay-Lac-Saint-Jean

Metalium

Fabrication

Montérégie

Tremcar

Fabrication

Montérégie

Précision SF Tech

Fabrication

Lanaudière

EcoloPharm

Fabrication

Montérégie

AGT Robotique

Fabrication

Mauricie

Les Industries Rainville

Fabrication

Montérégie

LABPLAS

Fabrication

Montérégie

Shalwin

Fabrication

Mauricie

Produits Métalliques Bussières

Fabrication

Chaudière-Appalaches

RG Solution

Construction, Fabrication

Estrie

Beaucinox

Fabrication

Chaudière-Appalaches

Metalilux

Fabrication

Laurentides

MegLab

Fabrication

Abitibi-Témiscamingue

Tiges 4 saisons

Fabrication

Centre-du-Québec

Paber Aluminium

Fabrication

Chaudière-Appalaches

MMS laser

Fabrication

Centre-du-Québec

Recyc PHP

Économie sociale, Fabrication

Centre-du-Québec

Les Branchés Lunetterie

Commerce de gros et détail, Fabrication, Services

Laurentides

Jambette

Fabrication

Chaudière-Appalaches

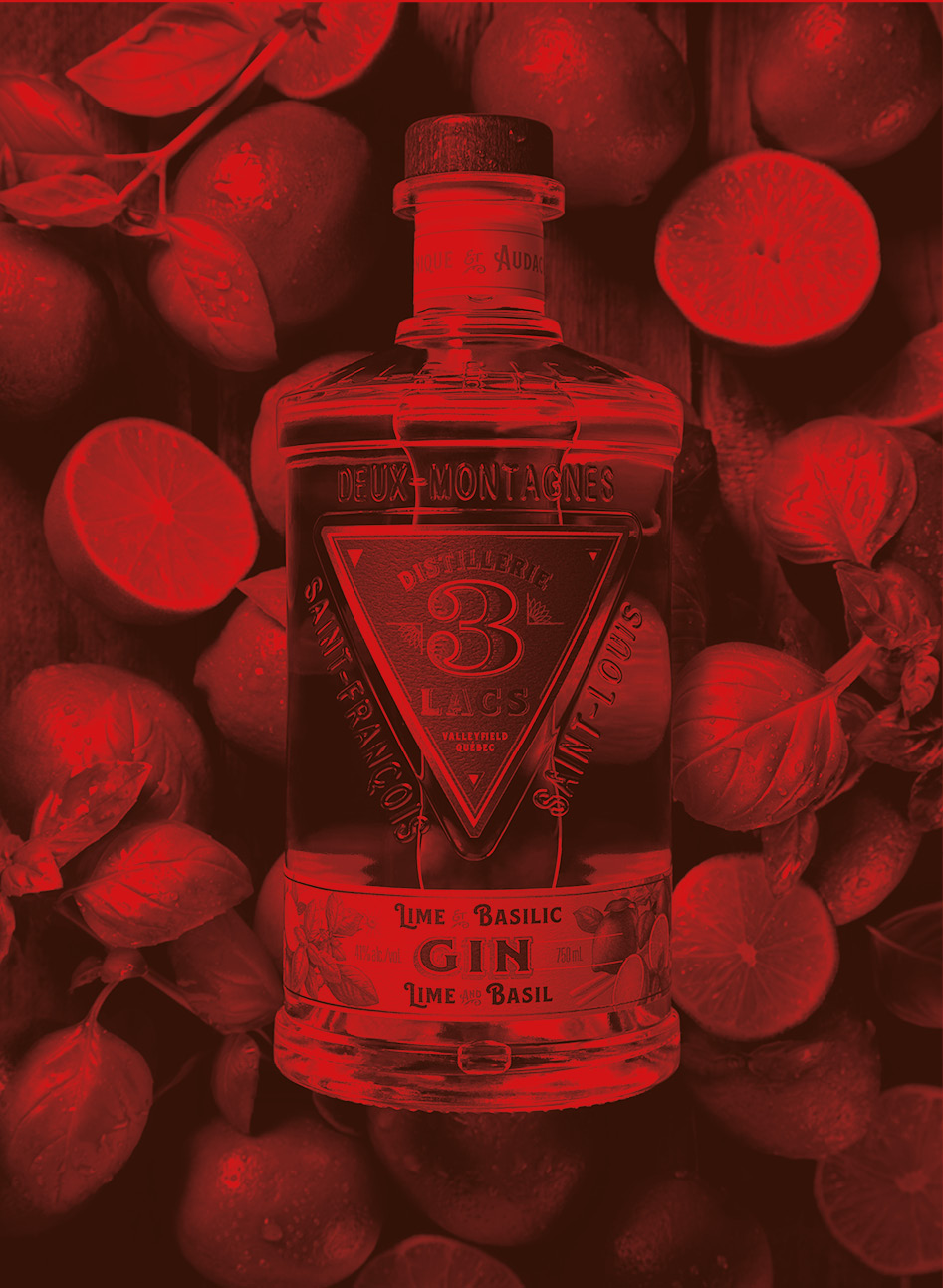

Distillerie 3 lacs

Fabrication

Montérégie

V Création

Fabrication

Laurentides

Ferreol

Fabrication

Capitale-Nationale

Les Industries Phomère

Fabrication

Capitale-Nationale

Read also

in the same

region

Chaudière-Appalaches

FC géosynthétiques

Construction

Chaudière-Appalaches

PH Tech – English

Construction, Fabrication

Chaudière-Appalaches

Everest Automation – English

Services

Chaudière-Appalaches

Paber Aluminium – English

Fabrication

Chaudière-Appalaches

Everest Automation

Services

Chaudière-Appalaches

PH Tech

Construction, Fabrication

Chaudière-Appalaches

Firebarns

Alimentation

Chaudière-Appalaches

J.M. Demers

Construction

Chaudière-Appalaches

Produits Métalliques Bussières

Fabrication

Chaudière-Appalaches

Beaucinox

Fabrication

Chaudière-Appalaches

Paber Aluminium

Fabrication

Chaudière-Appalaches

BEAUCE SPORTS

Commerce de gros et détail

Chaudière-Appalaches

Jambette

Fabrication

Chaudière-Appalaches

Mobile-Punch

Communication, technologie & Technologie de l'information

Chaudière-Appalaches

Enviro Confort

Construction

Chaudière-Appalaches

Gabion Express

Construction

Chaudière-Appalaches