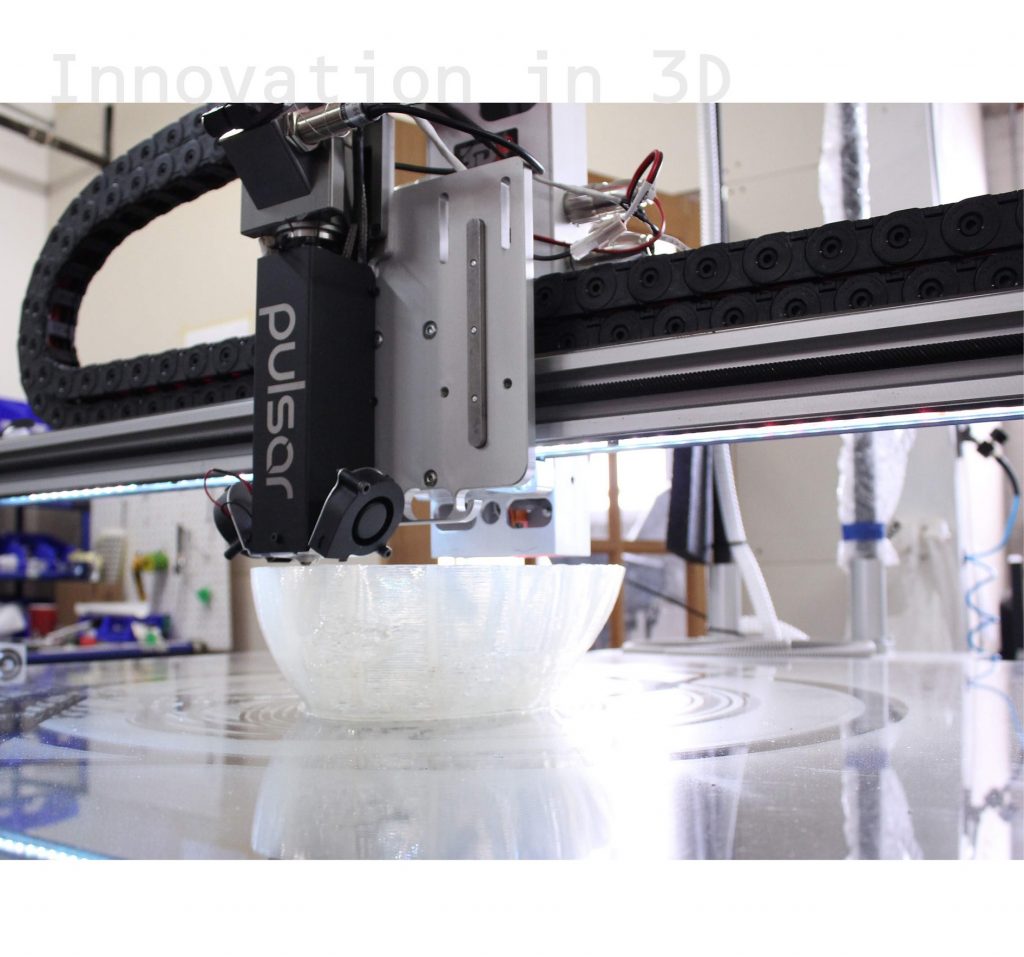

Founded in 2015, Dyze Design develops and manufactures high-performance components for 3D printers. Driven by innovative ideas and big ambitions, this foursome of young entrepreneurs is quickly putting its imprint on the international scene. The success of Dyze’s team is a testament to their creativity.

Share on social medias

Share on social medias

The genesis…

A new breed of inventor bursting with ideas

This fabulous entrepreneurial story begins with an idea

that blossomed in the mind of Philippe Carrier, then a student

at École de technologie supérieure.

At the time, Philippe cherishes the idea of making a drum set that would feature special drums. While talking with a friend with whom he is carpooling, the idea of using a 3D printer comes up. So, he buys one to help him achieve this objective.

As he is assembling the parts of his new acquisition, he realizes that the 3D printer is not very reliable.

“I found the source of the problem; it was the printer’s hot end. I told myself that with all the knowledge I had and the courses I was taking, I could do better.”

Armed with his knowledge and experience, Philippe sets about the task and develops printhead concepts.

“I designed prototype parts. I carried out tests.”

Philippe Carrier

An outsider looking in

Simon Duchaine, Philippe’s roommate at the time, sees the great potential in Philippe’s project. The entrepreneurial spark ignites in Simon’s imagination.

Do you want us to create a website for you, to come up with a company name?

Simon and Philippe work on this idea. It is one of many projects that Philippe is working on at the same time.

I didn’t expect that the response would be so strong, that there would be so much interest for the products we were developing.

The business idea does not come to fruition right away, with everyone being invested in their own projects. But it definitely lit

a lightbulb…

Maxence Gélinas-Guy

Instinct

From classmates to partners

At the ÉTS, Philippe discovers he shares a common bond with Maxence Gélinas-Guy, also a student in mechanical engineering. “Maxence was also interested in 3D printing. We did tests together and developed prototypes. We would work together on our school projects.”

It is in 2014, as part of a final year assignment at university, that Maxence, Philippe and other fellow students fine-tune their project of creating a high performance printhead. “Our project was about extrusion heads in 3D printing. This was the product that launched us into entrepreneurship!”

While the adventure is still in its infancy, Philippe discusses his project to design a printhead that he intends to market with a colleague he met during an internship. The latter shows a keen interest in collaborating with Philippe. The young professionals become business partners and put their heart and soul into this entrepreneurial project.

They use a hangar as makeshift premises.

We were separated by a shower curtain.

While Philippe focuses on prototyping and metal chip production, his partner works on the business plan.

Immediately after he completes his bachelor’s degree and throughout the summer of 2015, Philippe devotes himself full-time to this project, while his associate finalizes a master’s degree in innovation management.

Time is of the essence, as they want to settle in more comfortably when their two associates join the company full-time. “Our goal was to create a marketable prototype in 5-6 months.”

The team takes shape

In October 2015, Maxence, Jean-Sébastien Carrier, Phillipe’s brother, and Eric Bellemare, a mechanical engineering student involved in the final year assignment with Philippe, quit their jobs to also join them full-time.

“We said to ourselves that if we continued to be invested part-time, as if it were a plan B, we would always be outpaced by those who are fully committed.”

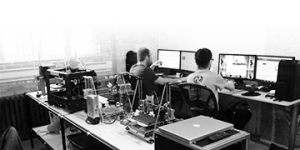

The team moves into their first office at 411 rue Moreau, in Montreal, near the Préfontaine metro station. “We still managed to have 600 square feet.”

There are five members in the organization during their first year.

Before the incorporation, we were in a general partnership for almost a year.

Eric is one of the first players to resign from the company, as he accepts a position with Tesla in the U.S. After that, Philippe’s first partner, who is president, leaves after 11 months. His departure creates opportunity for Simon Duchaine, a part-time consultant for the company, to become a Dyze partner.

We soon went to get Simon again. We needed his expertise to market our products.

Philippe Carrier, Simon Duchaine, Maxence Gélinas-Guy and Jean-Sébastien Carrier

Challenges on all fronts

Dyze’s four members have faith in their project, they persevere and are not daunted by the challenges facing an up-start business.

Financial stress is a reality they have to face. It puts significant pressure on the designers to develop a product as quickly as possible. “It took 18 months before we could cover fixed costs and pay ourselves a salary.”

Another major challenge for Dyze is finding investors. The 3D printer market is relatively unknown in Quebec, especially a decade ago.

Their expertise fulfils a need in a very niche industry. Furthermore, hardware has fallen out of favour with investors, who are focusing more on artificial intelligence, automation and software. However, the team is not letting this setback get them down.

Finding investors and being the flavour of the month in a sector in which you’re neither understood nor known in Quebec isn’t an easy thing to pull off.

Right from the start, the entrepreneurs make no compromises on their product’s quality and reliability. “We know that any product sent to a customer is a quality product!”

To achieve this, they carry out as many stages as possible in Quebec. Design, prototyping, assembly and final quality control are all carried out in Quebec.

We believed very strongly in the idea of doing as many things as possible locally in order to have some control.

The future will tell if their entrepreneurial instinct was right.

Potential investors do not understand why the company does not have its products assembled in China, in order to reduce production costs. At first sight, they are not sold on the concept of producing almost everything locally. “It’s been a hold up for many.”

Others criticize them for having too many shareholders at the head of the company. “Being four partners is a strength that explains, to some extent, our entrepreneurial success!”

The Dyze partners stick to their guns… They do not change their business model to get funding. The members are proud not to follow conventions and to do things their own way.

Forging your own path

International success

The saying “the grass is greener on the other side” is a perfect representation of the professional adventure of this foursome

of entrepreneurs.

The high-performance and reliable equipment they offer meets a real need in a market that is not well served by “cheap products or Asian knock-offs”.

Quebec is lagging behind in 3D printing. In fact, the province represents a very small share of the market. In reality, industries rely much more on these products in Europe, where several countries are a step ahead in terms of technology.

In 2016, the company finds its first manufacturing integrators, including Spanish company Dynamic Tools. “We jumped straight on the international bandwagon, a little naively, thinking that there was

demand there.”

The Dyze team seizes the opportunity. Thanks to word-of-mouth, the company builds a reputation and makes its mark on the international market.

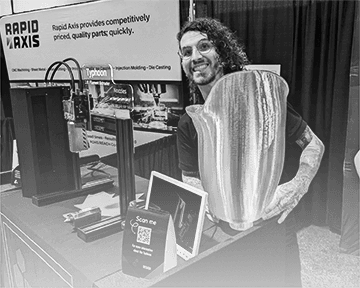

“We took part in trade shows in Europe. We talked to people from Spain, from Italy. Slowly but surely, we were getting new clients.”

Vision and values...

Ambitious goals

Initially, the target sector is the aftermarket, products aimed at “DIY” consumers.

We were faced with a certain clash in the industry, we realized that these consumers weren’t ready to pay the right price for our products.

On top of that, competition in this sector is fierce, which is proving unsuitable for their offer.

As a result, the Dyze team turn their attention towards integrator customers who manufacture state-of-the-art 3D printers for major companies such as General Motors, Bombardier and Airbus. “We sell to people in Industry 4.0, who are moving towards automation, who have industrial needs and challenges.”

During the course of 2018-2019, Dyze moves away from the consumer market and focuses its resources on this business opportunity – a relatively untapped market. Dyze has found its niche.

“Instead of lowering the quality and price of our products, we created bigger, more expensive products to sell to customers who were building bigger, more expensive printers.”

EXPANDING your horizons

The team wins first place in the “L’Accélérateur” competition, part of the “Alexandre et les conquérants” TV show. As a result, they have access to fast-track courses at École des hautes études commerciales (HÉC).

After that, the partners are part of the 2017 class of CENTECH incubator. The Dyze members now enjoy the status of “Alumni”. They also complete an ACET business accelerator program lasting about two years. In addition of developing their entrepreneurial project, these experiences allow them to interact with seasoned business people.

Through all this, we had consultants, coaches and mentors. People loved working with us, because we wanted to learn.

Sylvie Doré, a teacher at ÉTS responsible for everything to do with additive manufacturing, was an enlightening mentor. “She gave us her point of view and put us in touch with people who could help us. She was a great inspiration.”

Mentors

Another inspirational figure is Josée Paulin, of Apogée Conseil, who is described as the R&D specialist. She has spent many hours reviewing processes, providing explanations, advice and suggesting reading material. “She even took me on a tour of companies around Sherbrooke. She had a very unique energy.”

The entrepreneurs foster a great relationship with ACET and Développement économique de Longueuil (DEL). “They give us access to incredible people.” Among them is Pierre Hamel, a teacher at Université de Sherbrooke with a knack for project management.

“They are people who look at our project from the outside. They are driven. They see that we’re all ears, that we’re putting their advice into practice and that they generate results. When we have subsequent meetings, we’re already on to the next topic!”

Intellectual property expert Jean-Sébastien Brière is a coach of choice, helping the members to elevate their game and get to the next level. “He has brought us up to play in the big leagues.”

Always keen to learn from others, Jean-Sébastien Carrier, the current president of Dyze, has been a member of Regroupement des chefs d’entreprises du Québec, now known as EntreChefs PME, since 2019.

Sound advice

Sometimes, it’s good to talk to people who have seen it all, to understand how to navigate and adapt our strategies to the current context.

The partners are open to the advice and teaching of mentors and coaches. They are grateful for all the support they receive. However, they rely first and foremost on their own judgment and instincts.

“We’ve always listened to the advice we’ve been given. We never claimed to have all the answers. We remain humble. When we don’t follow advice, we always explain the reason why.”

Seeking knowledge

Creating a buzz for science

In 2019, the entrepreneurs create a workshop to introduce primary school children to 3D printing and modeling. One of the aims is to introduce students to the field of science in order to encourage them to pursue studies in STEM (science, technology, engineering and mathematics).

We’re giving back to the community and, at the same time, we’re preparing the next generation.

Unfortunately, the entrepreneurs have put this workshop on hiatus as a result of the COVID-19 sanitary measures, but they intend to resume it and even adapt it for secondary school students.

“We would like to have a real impact and educate students about the prerequisites for studying science. We have targeted students from the 6th grade all the way up to secondary 3.”

When brains turn to gold

The R&D department’s young, creative team accounts for two-thirds of the organisation’s employees. If the company is so renowned for its innovative ideas and high-performance products, it is because the entrepreneurs are banking on the creative juices of its brain power.

“Even if 3D printing isn’t a well-known sector in Quebec, the brains that develop these products come from here. The programs at ÉTS, Polytechnique, Université de Sherbrooke and Université Laval are producing skilled specialists.”

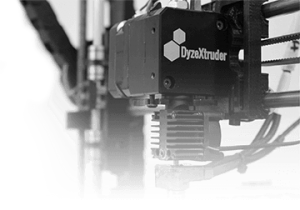

Over the last few years, their expertise has been constantly refined. “If you compare hotend prototypes from 2015 with those of today, there has been a great evolution!” The company is developing the same product and has not spread itself too thin. It is setting the standard for the industry.

Environmental footprint

The extrusion head manufactured by Dyze represents approximately one tenth of a printer’s components. The quality of this part increases the lifespan of the machine. “Our strength is that we can reduce the unit cost of manufacture.”

Environmentally and financially, the company makes it advantageous to design parts using 3D printing rather than a more traditional method, which uses expensive moulds and forces minimum volume per orders. “We offer a local alternative to designing in China.”

The use of the extrusion head also reduces electricity costs. A significant competitive advantage.

The entrepreneurs note that the company receives little praise and has little visibility in this respect.

It’s practically always the manufacturer who has integrated our head that takes the honours when it comes to the environmental aspect.

Local option

Geek advices

The entrepreneurs are keen to share advice, such as the importance of surrounding yourself with the right people right from the start and launching a company with people who have complementary skills and personalities. “It’s important to have a diverse team.”

Drawing up a shareholder’s convention that brings together all the members from the outset of the business project is a winning strategy in the event of any conflict. Like in a marriage, it is when you are happily married that you need to set out the parameters of a contract setting out how the company will operate and the commitments of all parties involved.

Putting it down on paper when there’s a good atmosphere can save a lot of problems!

Other tips include taking time to cultivate the relationship between partners, supporting each other and not hesitating to resolve conflicts. Also, one member stresses the importance of being on the lookout for early signs of mental health problems.

I think more attention has been paid to mental health in recent years.

Reaching out to others, asking questions and asking for help, advice and mentoring are recommendations that are just as relevant for a new entrepreneur. “Accept feedback and integrate it into the company, remembering that the people you went to for support have experience.”

Behind the scenes…

The meticulous manager

Jean-Sébastien Carrier

Co-Founder and President

With a degree in computer science from Université de Sherbrooke under his belt, Jean-Sébastien is invited by his brother Philippe to become a member of Dyze. Blessed with a Cartesian mind, keen intelligence and a taste for compartmentalization, he initially serves as software director, but, through necessity, quickly climbs the company ladder to the top. Although he describes himself as an introvert, he manages to transcend his anxiety and hone his communication skills when making sales pitches.

“After I made my first sales pitch, I was advised to find someone else to do them. Four months later, I was winning a competition organised by the HÉC!”

The determined jokester

Simon Duchaine

Partner, Chief Marketing & Sales Officer

With a bachelor’s degree in public communications from Université Laval, Simon works for an advertising agency before joining Dyze, where he becomes one of the first key employees. His rich background in creative advertising and acute sensibility allow Simon to have a unique perspective on entrepreneurship and offer a great addition to the team. Naturally optimistic and brimming with enthusiasm, he is a perfect ally.

“I am an emotional guy – very passionate, creative, with great instincts. Sometimes, I wear rose-coloured glasses. I’m very positive!”

The pragmatic ally

Maxence Gélinas-Guy

Co-Founder and Production Manager

Maxence met Philippe Carrier while he was completing his bachelor’s degree in mechanical engineering at École de technologie supérieure (ÉTS). The Maxence-Philippe duo is especially efficient thanks to the way they complement each other. Maxence, who is firmly rooted in reality, has a knack for assessing a project’s feasibility and finding concrete ways of turning his colleague’s flamboyant ideas into reality.

“I’m a very technical guy. I can predict how things will ultimately turn out. I have this ability to take an idea and figure out how to apply it in the real world.”

The skilful inventor

Philippe Carrier

Co-Founder and Chief Research Officer

With a bachelor’s degree in mechanical engineering from ÉTS, Philippe is the driving force behind Dyze Design. Blessed with an inventive mind, he is driven by a host of ideas and projects that he shares with his partners. The creator does not shy away from thinking outside the box. Philippe is highly structured and has an impeccable work ethic. He methodically documents the procedures he creates, so that his colleagues can follow his reasoning – this is how this skilful engineer passes on his knowledge.

“I have a creative personality; I’m prepared to take risks and I think differently than those who follow the trend.”

Building a team

An outline of the future…

Innovation is sophistication

The R&D team aims to create products with smarter, more sophisticated systems. Instead of looking solely at mechanics,

Dyze is focusing more and more on electronics and software.

“What we want to do is integrate sensors to get more data on the whole process.”

Meeting the 3D printing needs of companies in the aerospace industry, in particular, who use highly expensive engineering materials and have precise objectives to meet, Dyze’s innovative team has no choice but to aim for excellence!

Our products are evolving in line with the requirements of Industry 4.0.

Dyze design – English

1505, Saint-Thomas, bureau 100

LeMoyne (Québec) J4P 3S2

438 238-1400

dyzedesign.comPublishing Director: Audrey Dallaire

Author: Caroline Lepage

Translator: Frédérick Poulin

Graphic design: Liliane Racine

Graphic designer: Marie-Hélène Taillon

Proofreading: Céline Chabot